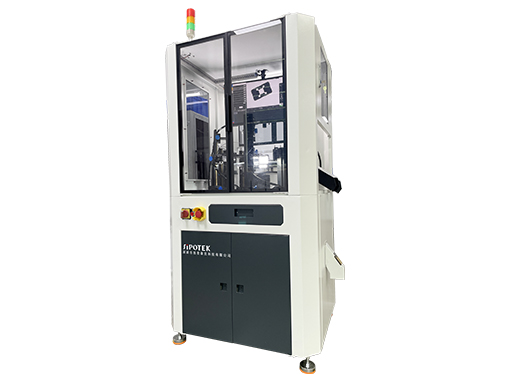

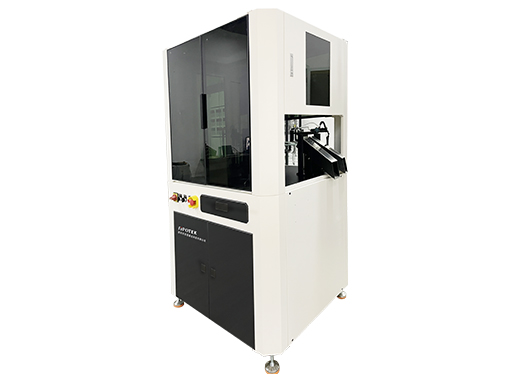

CCD vision inspection equipment, a device that uses CCD (charge-coupled device) cameras and related image processing technology to perform detection and analysis. Used to detect surface defects, foreign bodies, dimensional deviations and other problems. CCD cameras are capable of capturing high-resolution images, and image processing algorithms can quickly and accurately analyze the images in order to identify any product defects in a timely manner. CCD vision inspection equipment is widely used in various industries, such as electronics manufacturing, automotive industry, food processing, etc., to ensure product quality and improve production efficiency.

High resolution: CCD cameras have high resolution and can capture fine details, which is suitable for accurate detection and analysis of products.

Rapid inspection: CCD vision inspection system can quickly capture, process and analyze image data to achieve efficient product inspection and quality control.

Stability: CCD camera has high stability and reliability, suitable for long-term continuous operation of the production line.

Strong adaptability: CCD vision inspection system can adapt to different lighting conditions, product shape and color and other diverse conditions of detection needs.

Automation: CCD vision inspection system can achieve automated product inspection and classification, reduce manual intervention, improve production efficiency.

Flexibility: CCD vision inspection system can be configured and adjusted according to the testing needs of different products, with strong flexibility.

Real-time: CCD vision inspection system can monitor and feedback product inspection results in real time, find problems in time and take measures.

Device type | High speed cloud disk tester (Glass disk) |

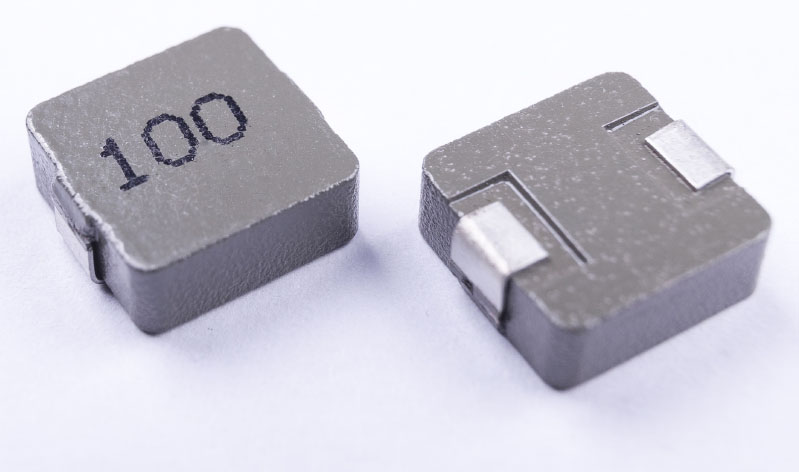

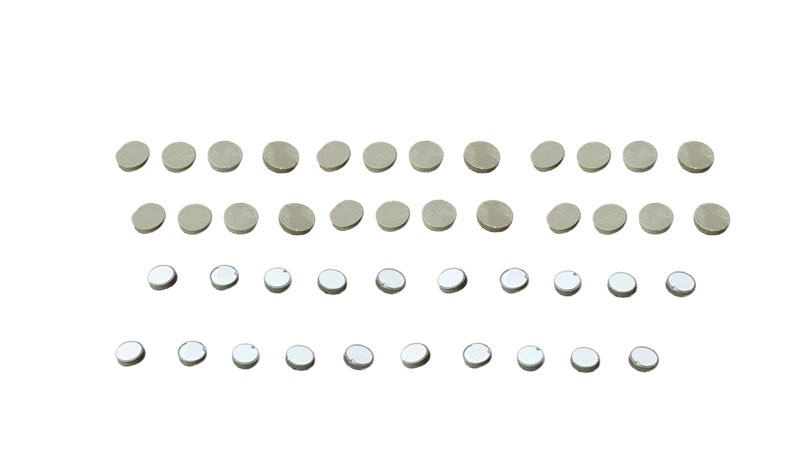

| Scope of application | It is suitable for the detection of rubber parts, precision hardware parts, automobile, mobile phone parts, plastic parts, electronic parts and other high-precision products. |

| turntable | Special ring glass turntable |

| Optical system | Germany high rate CCD industrial camera, Japan imported lens, professional light source system |

| Number of cameras | Standard 1 (optional 1 ~ 8) |

| Control system | Germany Siemens Industrial Computer |

| Image detection software | Siptech Vision inspection System |

| Feed system | Special feed guide rail, a set of vibration disk equipment, automatic feed storage hopper equipment (optional) |

| Packaging system | Automatic counting and packing machine (optional) |

| Detection speed | 200 to 1200 PCS/min |

| precision | Up to ±0.01mm |

| Recommended inspection size | 0.1 ~ 50mm |

| Detection quality | 0.1 to 100g |

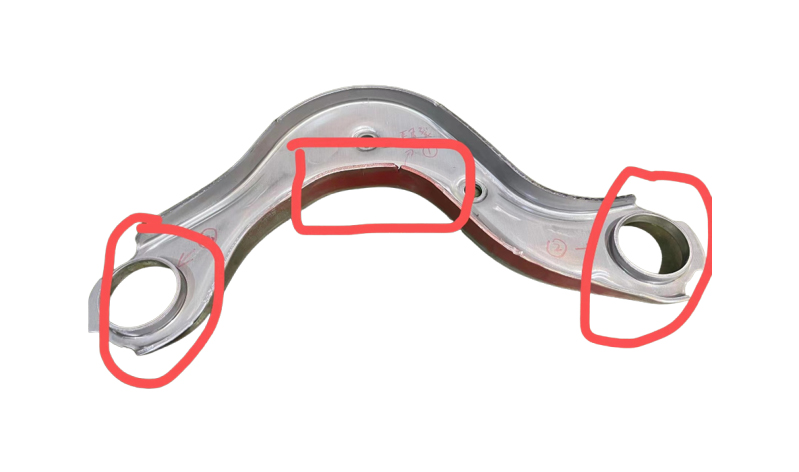

Detection index | Appearance size detection: outer diameter, inner aperture, opposite side, diagonal, length, height, concentricity, roundness, step size, Angle, sharpness, etc |

| Defect detection: 360-degree teeth, rotten teeth, bad teeth, oblique teeth, poor knead teeth, internal burrs, lack of material, internal hole blockage, cracking, burrs, solder joint area, mark, there are no internal teeth, all functional detection of standing flat head screw tooth parts |

| Supply voltage | Two-phase 220V, 50Hz |

| Rated power | 1kW |

| Atmospheric pressure | The air pressure is not less than 0.35 ~ 0.7MPa |

| Equipment weight | About 500kg |

| Operating temperature | -3 ° C to 45 ° C |

| Storage temperature | -20℃ ~ 60℃ |

| Equipment size | 1000mm(L)×1000mm(W)×1800mm(H) |