The advantage and principle of visual screening machine in crack detection

The advantage and principle of visual screening machine in crack detection

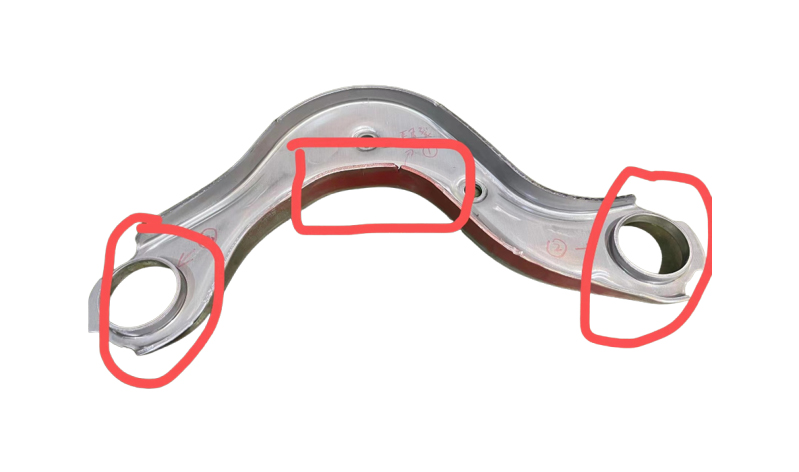

In modern industrial production, the quality of mechanical parts is related to the stability and safety of the entire production process. Especially for the important mechanical structure of the swing arm, if the crack problem is not found and solved in time, it may lead to equipment failure and even lead to production accidents. In order to ensure product quality and safety, crack detection has become an indispensable step. Traditional crack detection mostly relies on manual visual inspection or simple mechanical inspection equipment, but these methods are usually inefficient, easy to miss small cracks, and require a lot of labor costs. The emergence of visual screening machines provides a new solution to this problem.

The working principle of visual screening machine

Visual screening machine is an automatic inspection equipment based on image processing technology. It uses high-precision cameras, sensors and specialized image processing algorithms to quickly scan and analyze objects under detection. For swing arm crack detection, the working principle of the visual screening machine can be simply divided into the following steps:

Image acquisition: With a high-resolution industrial camera, the visual screening machine can acquire the surface image of the swing arm in real time. In order to ensure the visibility of cracks and the accuracy of detection, a multi-angle shooting system is usually equipped to capture images from different directions.

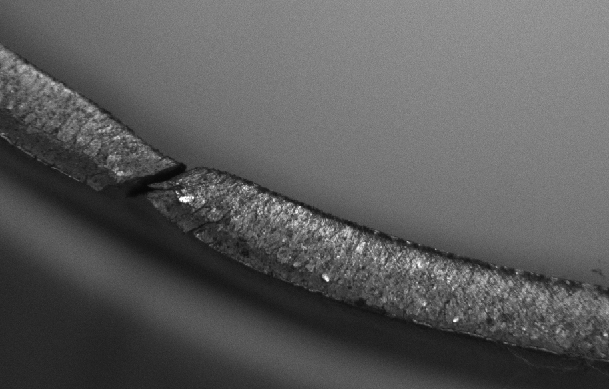

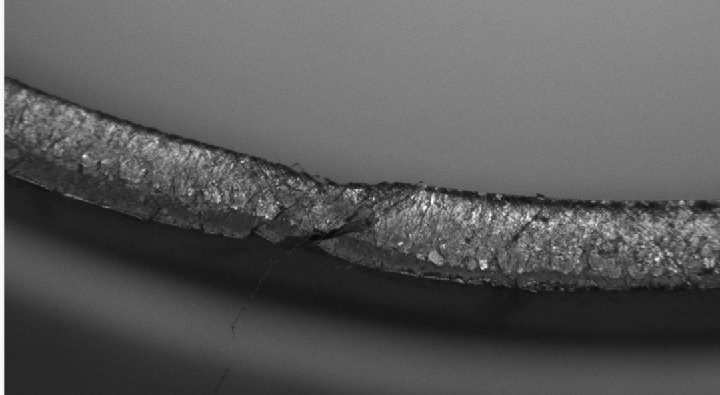

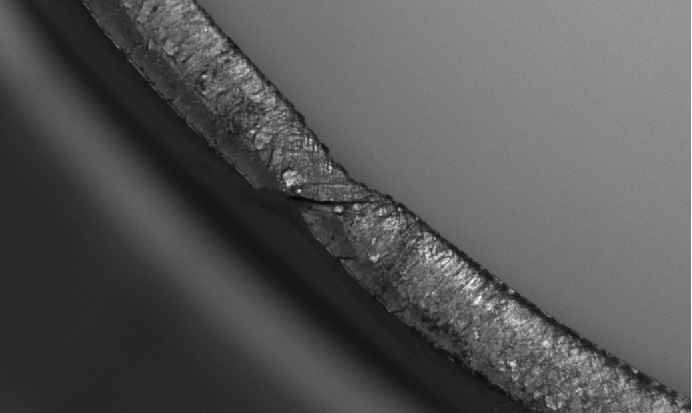

Image processing: The captured images will be analyzed by specialized processing algorithms. The process includes edge detection, gray adjustment, noise filtering and so on. The detection of cracks, in particular, relies on high-precision image processing techniques that can identify subtle structural changes.

Crack identification and classification: The visual screening machine compares the normal surface with the abnormal crack area through pattern recognition technology, and accurately locates the location, shape and severity of the crack. The system can also automatically classify different crack characteristics (such as length, width, depth, etc.) to help technicians determine whether the part needs to be replaced or repaired.

Core benefits of visual screening machines

Compared with traditional manual detection methods, visual screening machines have significant advantages in detecting swing arm cracks:

High-precision detection: The visual screening machine can detect tiny cracks that are difficult to find with the naked eye, especially some cracks hidden in complex surface structures. High resolution image combined with advanced processing algorithm makes its detection accuracy far superior to manual visual inspection.

Fast and efficient: The visual screening machine can complete the detection task of a large number of swing arms in a very short time. For factories that need efficient production, this can greatly improve production efficiency and avoid the inefficiency and error of human detection.

Non-contact detection: Different from the traditional mechanical inspection, the visual screening machine uses non-contact detection to avoid wear and damage to the parts, especially for some parts with high surface quality requirements.

Application scenario and future development of visual screening machine

Practical application of swing arm crack detection

With the continuous progress of visual screening technology, its application in industry is more and more extensive, especially in machinery manufacturing and automobile manufacturing, swing arm crack detection has become one of the key links to improve product quality and production efficiency.

In automobile manufacturing, the swing arm is an important part of the vehicle suspension system, and its strength and durability directly affect the safety performance of the vehicle. Therefore, the detection of the swing arm crack is not only the requirement of quality control, but also the basic guarantee of safety standards. The crack detection of the swing arm through the visual screening machine can not only increase the detection speed, but also ensure that the safety performance of each product is up to standard and reduce the risk of accidents.

In addition to the automotive industry, visual screening machines also play an important role in high-demand industries such as aerospace, rail transit, and precision machinery. These industries have extremely high requirements for the strength and durability of components, and any slight crack can cause serious accidents. Therefore, the high precision and high performance inspection capabilities of visual screening machines provide vital quality assurance for these high-end manufacturing areas.

Detection effect

crack

Future development trend: Integration of artificial intelligence and visual screening

Although the current visual screening machine already has a high detection accuracy and efficiency, with the advancement of Industry 4.0, the combination of artificial intelligence (AI) and visual screening technology will be an important development trend in the future. AI technology will give the visual screening machine higher learning ability, so that it can continuously self-optimize in long-term operation and improve the detection effect.

Self-learning and algorithm optimization: With AI, visual screening machines can automatically adjust and optimize their image processing algorithms to identify more complex crack patterns by analyzing a large number of crack samples. This will significantly improve the accuracy of detection, especially when detecting some irregularly shaped cracks, and the participation of AI will greatly reduce the misjudgment rate.

Predictive maintenance: Future visual screening machines will also have predictive maintenance functions that can give early warning of cracks, helping companies maintain equipment in advance to avoid large-scale shutdowns or accidents. This predictive maintenance will greatly improve the production safety and economic benefits of enterprises.

Big Data and cloud computing support: With the development of the Industrial Internet of Things, visual screening machines can upload inspection data to the cloud for big data analysis. Through the analysis of historical data, enterprises can better understand the status and service life of equipment, and further optimize the production process.

The introduction of visual screening machine provides an efficient and accurate solution for the crack detection of swing arm. Through advanced image processing technology, the visual screening machine can quickly and reliably identify various crack problems to help enterprises improve product quality and production efficiency. With the deep integration of artificial intelligence and industrial Internet of Things technology, visual screening machines will play a more important role in the future industrial manufacturing, helping the comprehensive upgrade of intelligent manufacturing.

-

Service hotline

19926638772