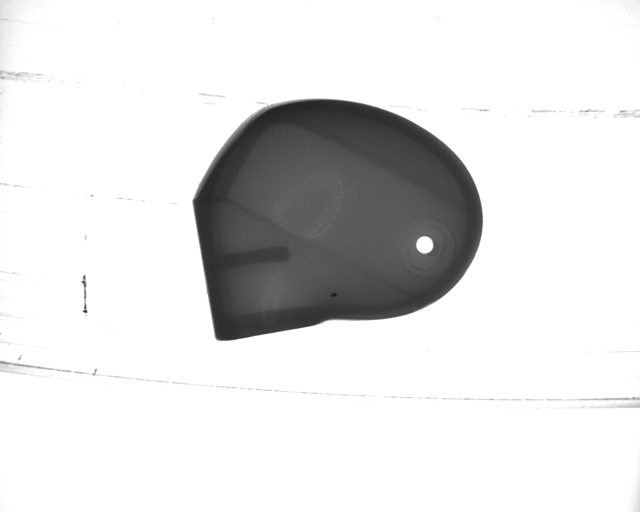

Glass plate vision inspection machine, used to detect the quality of glass plate products equipment. Use vision technology, cameras and image processing algorithms to detect surface defects, foreign objects, cracks and other problems placed on the glass plate. By analyzing and comparing image data, the vision inspection machine can quickly and accurately identify any unqualified glass plate products, thereby ensuring product quality and production efficiency.

Surface defect detection: detection of product surface defects, scratches, dents, bubbles, stains, etc.

Color recognition: Identify whether the color of the product meets the standard, and detect whether there is color difference or abnormal color.

Foreign body detection: Detect whether there are foreign bodies on the surface of the product, such as impurities, foreign particles, etc.

Missing parts testing: Testing products for missing parts or incomplete parts.

Coating uniformity test: Test the uniformity of the product coating to ensure that the coating quality meets the requirements.

Appearance consistency test: Test the consistency of the appearance of the product, such as shape, size, appearance, etc., whether it meets the standard.

Identification detection: detection of product identification, printing text, pattern, etc., is clear and accurate.

Surface smoothness test: test the smoothness of the product surface to ensure that the surface quality meets the requirements.

Edge detection: detection of product edge integrity, flatness, whether there are burrs and other problems.

Real-time feedback and control: Provide real-time feedback of defect detection results, and integrate with the control system to achieve real-time control and adjustment.

Automatic decision: Based on the appearance defect detection results, automatic decision, such as quality determination, product classification, etc.

Device type |

High speed cloud disk tester (Glass disk) |

Scope of application |

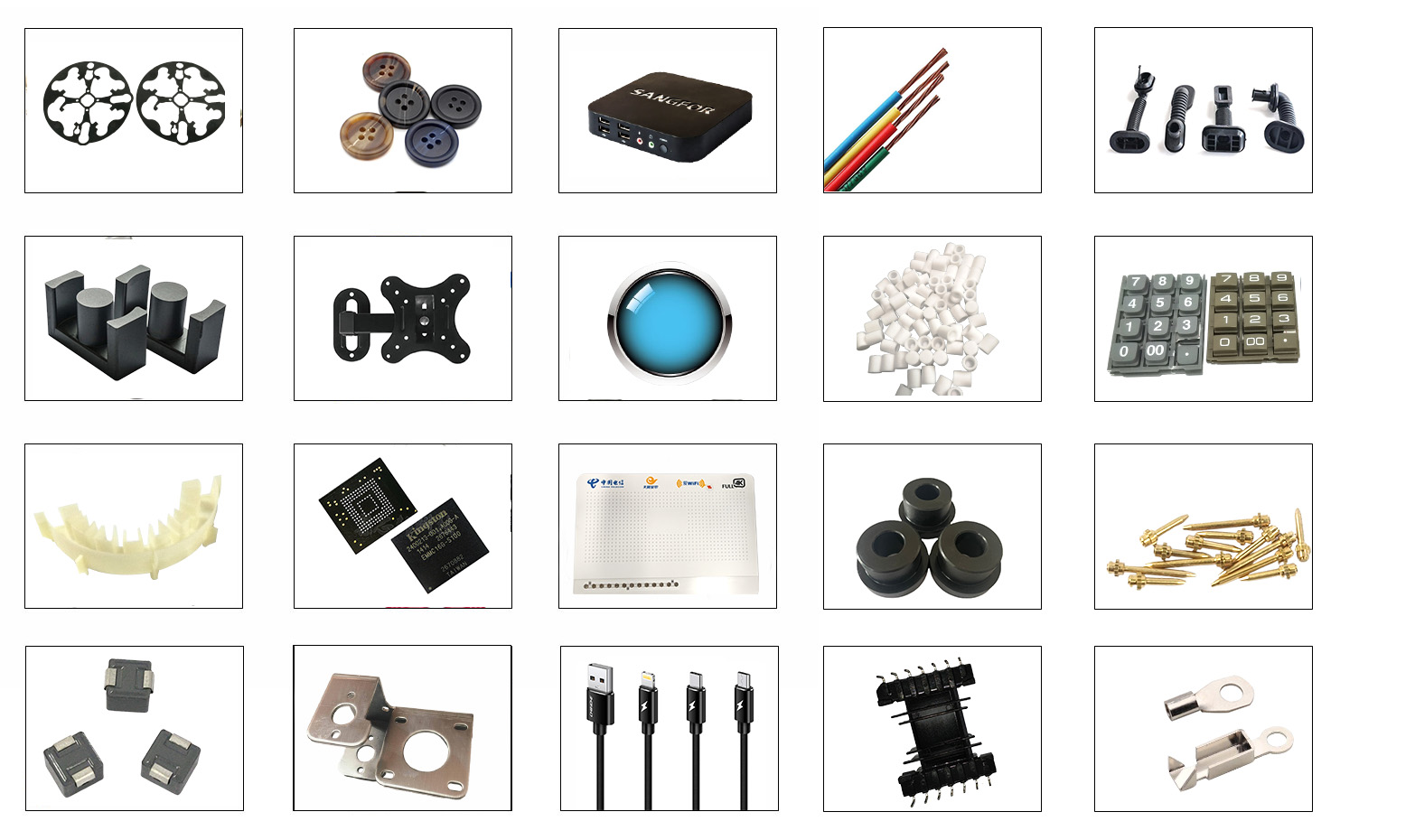

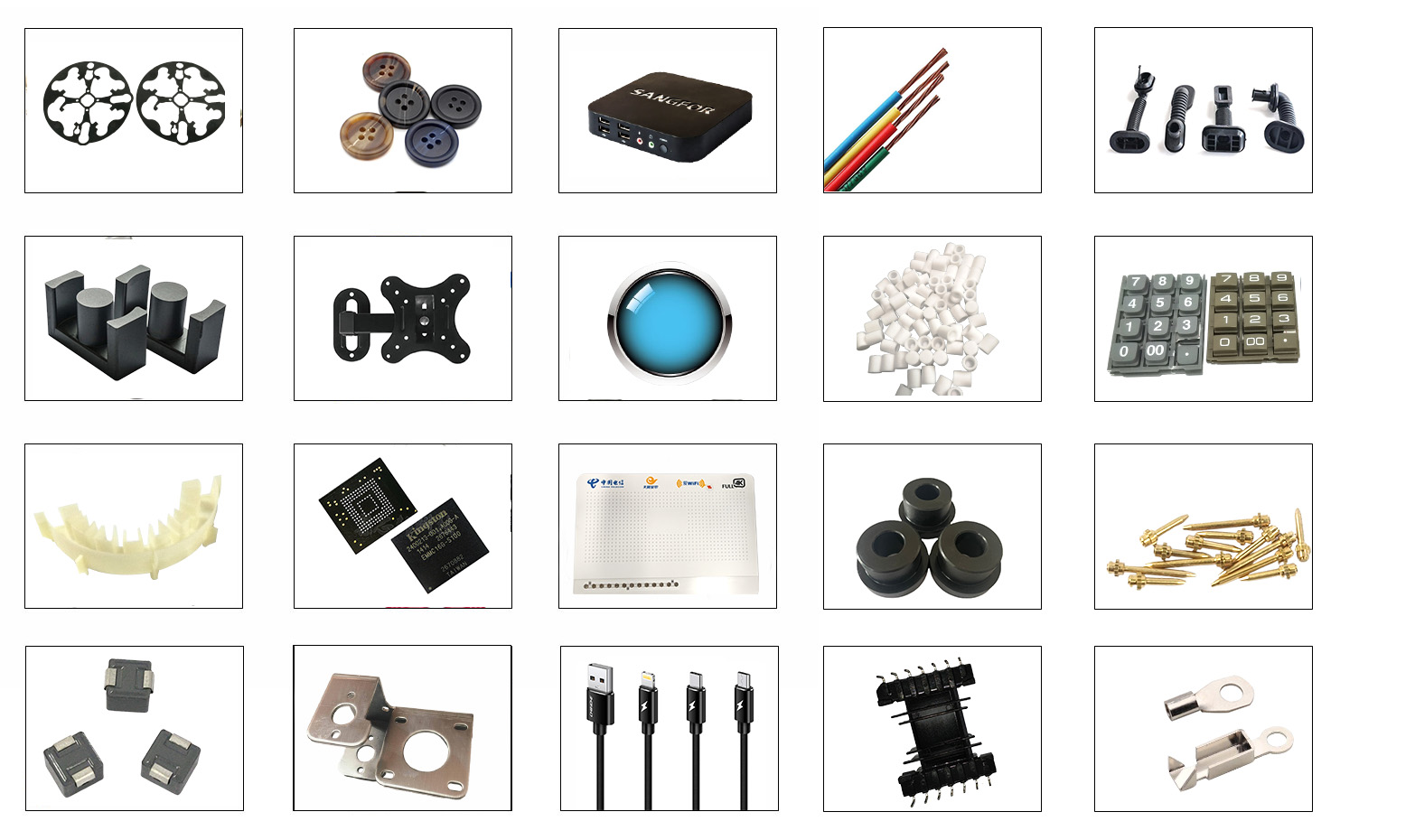

It is suitable for the detection of rubber parts, precision hardware parts, automobile, mobile phone parts, plastic parts, electronic parts and other high-precision products. |

turntable |

Special ring glass turntable |

Optical system |

Germany high rate CCD industrial camera, Japan imported lens, professional light source system |

Number of cameras |

Standard 1 (optional 1 ~ 8) |

Control system |

Germany Siemens Industrial Computer |

Image detection software |

Siptech Vision inspection System |

Feed system |

Special feed guide rail, a set of vibration disk equipment, automatic feed storage hopper equipment (optional) |

Packaging system |

Automatic counting and packing machine (optional) |

Detection speed |

200 to 1200 PCS/min |

precision |

Up to ±0.01mm |

Recommended inspection size |

0.1 ~ 50mm |

Detection quality |

0.1 to 100g |

Detection index |

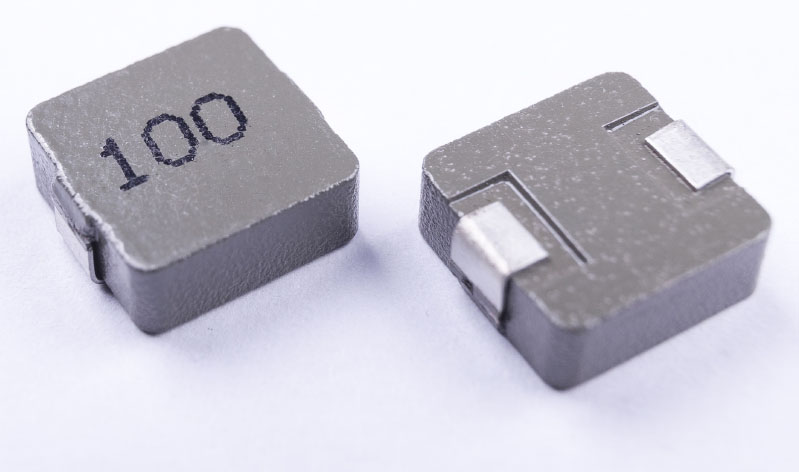

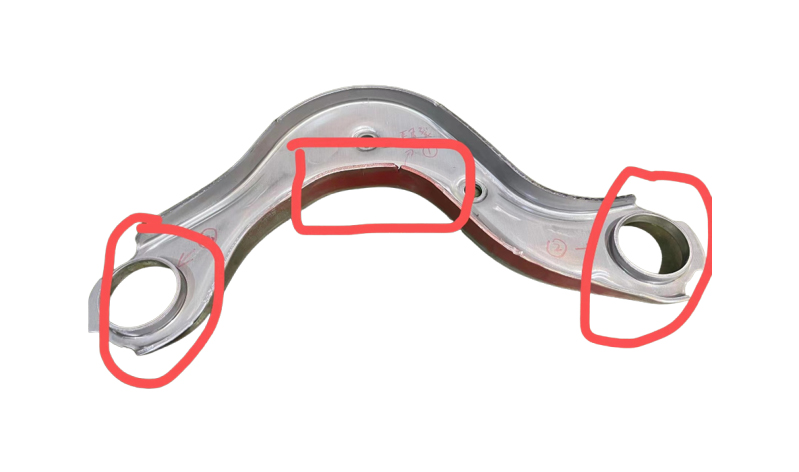

Appearance size detection: outer diameter, inner aperture, opposite side, diagonal, length, height, concentricity, roundness, step size, Angle, sharpness, etc |

Defect detection: 360-degree teeth, rotten teeth, bad teeth, oblique teeth, poor knead teeth, internal burrs, lack of material, internal hole blockage, cracking, burrs, solder joint area, mark, there are no internal teeth, all functional detection of standing flat head screw tooth parts |

Supply voltage |

Two-phase 220V, 50Hz |

Rated power |

1kW |

Atmospheric pressure |

The air pressure is not less than 0.35 ~ 0.7MPa |

Equipment weight |

About 500kg |

Operating temperature |

-3 ° C to 45 ° C |

Storage temperature |

-20℃ ~ 60℃ |

Equipment size |

1000mm(L)×1000mm(W)×1800mm(H) |

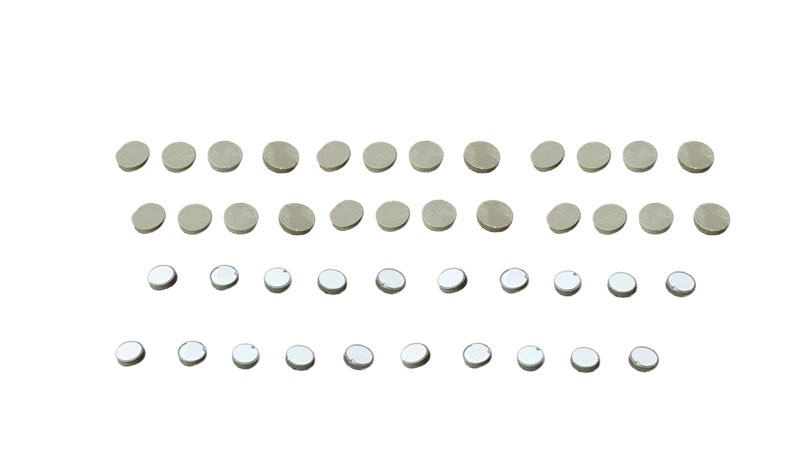

Automobile parts Semiconductor chip Metal hardware

Magnetic material Rubber seal ring