Belt visual inspection equipment is used for visual inspection equipment on automated production lines, mainly used for testing and quality control of products on the conveyor belt.

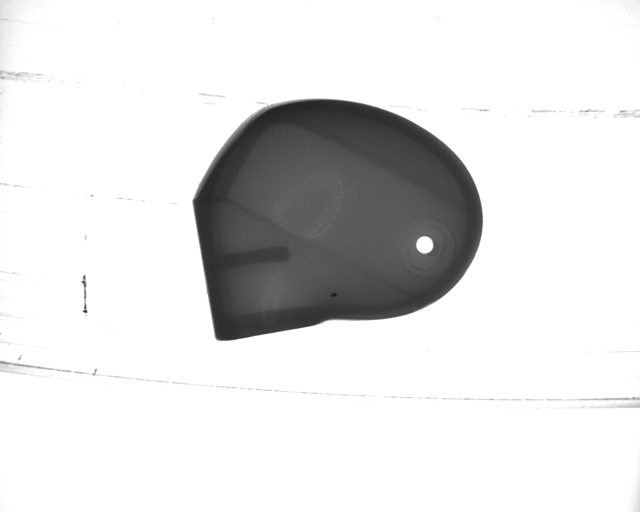

Products on the conveyor belt are detected and analyzed in real time through cameras and image processing systems.

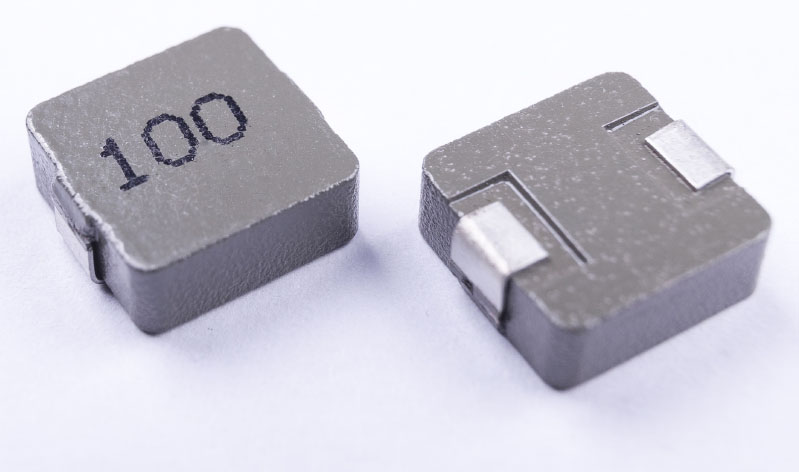

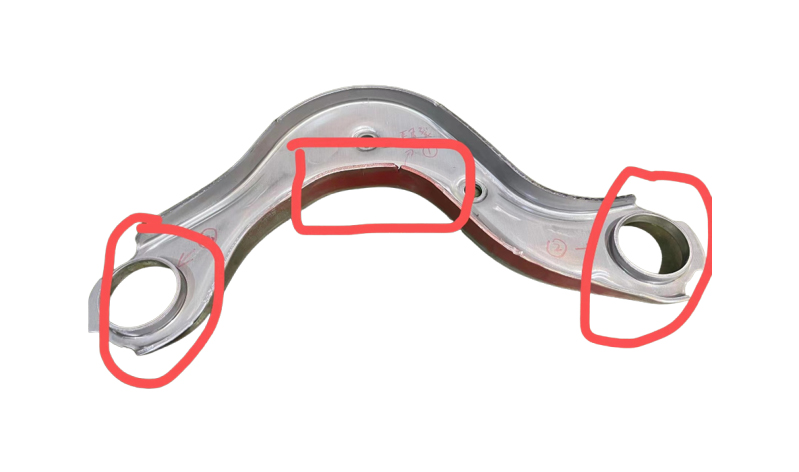

Product defect detection: Through the visual system to detect products, identify and detect defects on the product, such as cracks, dents, damage, etc.

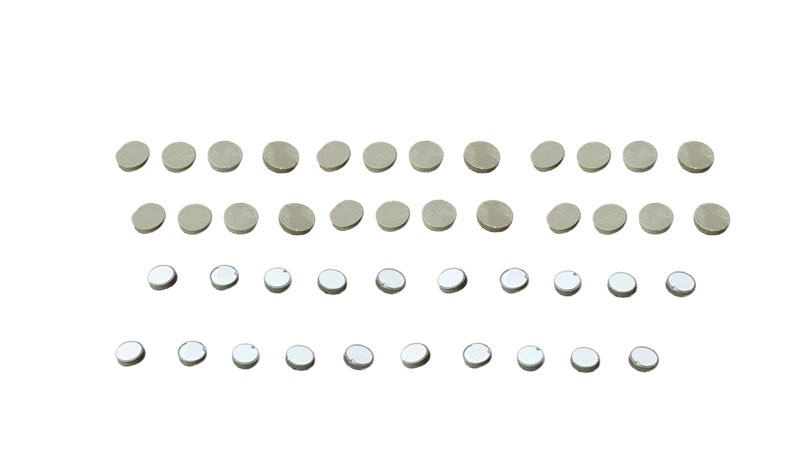

Size measurement: Measure the size, length, width and other parameters of the product to ensure that the product meets the specifications.

Shape recognition: Identify the shape features of the product, including curves, angles, contours, etc., to ensure that the shape of the product meets the design requirements.

Color recognition: Identify the color of the product, detect whether the product meets the color requirements, suitable for product lines that require color consistency.

Foreign body detection: Detect whether there are foreign bodies or impurities on the surface of the product to ensure product quality and safety.

Positioning detection: accurately locate the product position to ensure that subsequent processing, packaging and other processes are accurate.

Character recognition: identify the text, bar code, two-dimensional code and other information on the product to achieve automatic data collection and traceability.

Automatic classification and sorting: According to the test results, the products are automatically classified, sorted or eliminated unqualified products to improve the efficiency of the production line.

Data recording and analysis: Record inspection data, generate reports, support data analysis and traceability, and help enterprises with quality management and process optimization.

Device type | Pipeline tester |

Scope of application | It is suitable for the detection of rubber parts, precision hardware parts, automobile, mobile phone parts, plastic parts, electronic parts and other high-precision products. |

Optical system | Germany high rate CCD industrial camera, Japan imported lens, professional light source system |

Number of cameras | Standard 1 (can be configured according to demand) |

Control system | Germany Siemens Industrial Computer |

Image detection software | Siptech Vision inspection System |

Feed system | Conveyor belt |

Detection speed | 60 ~ 300 PCS/min (depending on product size) |

Recommended inspection size | 30 ~ 200mm |

Detection quality | 5 ~ 500g |

precision | Up to ±0.01mm |

Detection index | Detection of missing, misloading, mixing, defect detection, size detection, screen printing detection, etc |

Supply voltage | Two-phase 220V, 50Hz |

Rated power | 1kW |

Atmospheric pressure | The air pressure is not less than 0.35 ~ 0.7MPa |

Equipment weight | Approx. 150kg |

Operating temperature | -3 ° C to 45 ° C |

Storage temperature | -20℃ ~ 60℃ |

Equipment size | 1900mm(L)×500mm(W)×1300mm(H) |