Assembly line visual inspection equipment relates to a visual inspection technology applied on a production line. Use cameras, sensors and image processing software to detect the quality and integrity of products on the assembly line in real time. By collecting product images or data, the system can automatically identify product defects, foreign bodies, size deviations and other problems, and trigger alarms or automatically eliminate unqualified products when needed. Line vision inspection can help manufacturers improve production efficiency, reduce human error, and ensure product quality is up to standard.

automate

Pipeline visual inspection is an automatic inspection method, which can realize the automatic detection, analysis and processing of products, reduce manual intervention and improve production efficiency.

High efficiency

By using high-speed cameras and fast image processing algorithms, pipeline vision inspection can complete the inspection of a large number of products in a short time to achieve efficient production.

accuracy

With advanced image processing technology, pipeline visual inspection can realize high-precision detection of product defects, dimensional deviations and other issues to ensure product quality meets standards.

real-time

Line visual inspection can monitor product status in real time, find problems in time and take corresponding measures to avoid bad products from continuing to flow into the production line.

flexibility

Visual inspection systems usually have flexible configuration options that can be customized according to the characteristics and requirements of different products, and are suitable for a variety of production scenarios.

Data traceability

The pipeline visual inspection system can record and store the data and images in the inspection process, realize the traceability and analysis of product quality, and provide a basis for the optimization of the production process.

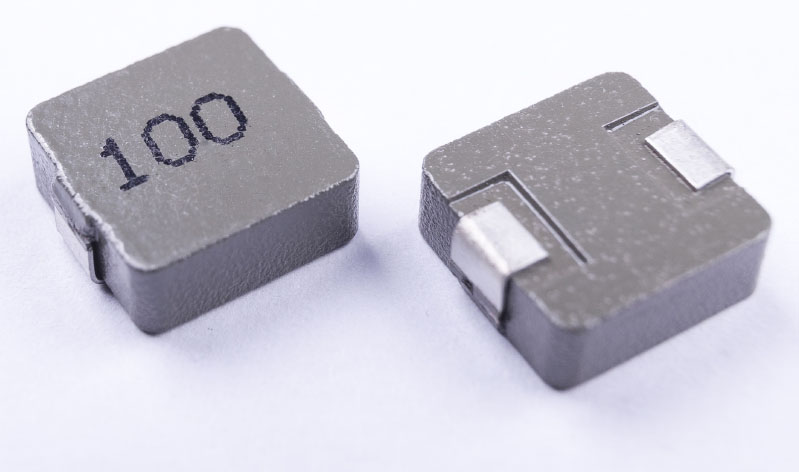

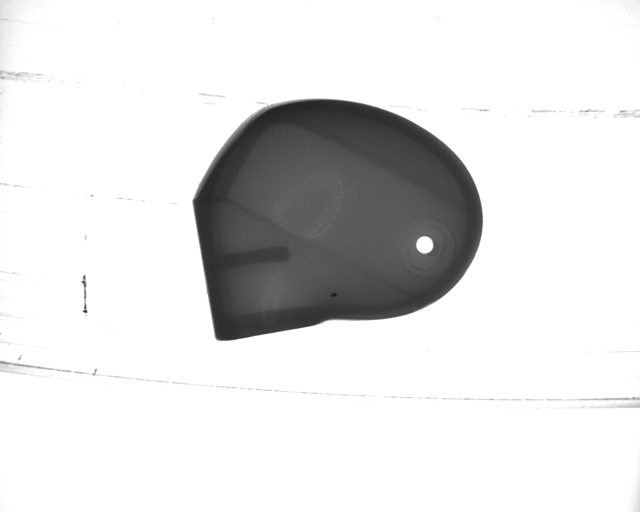

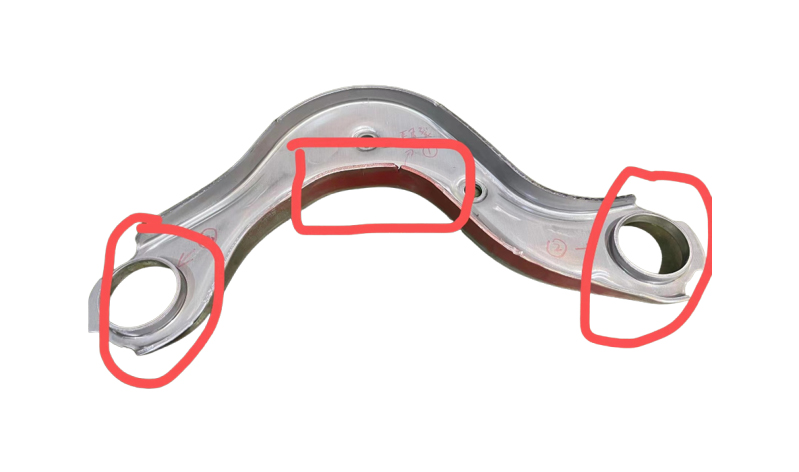

Defect detection: Detect defects on the surface of the product, such as cracks, scratches, bubbles, etc., to ensure product quality.

Dimensional measurement: Measurement of product size, shape and position to ensure product compliance with specifications.

Foreign body detection: Detect foreign bodies or impurities in products, such as metal sheets, foreign particles, etc., to prevent unqualified products from entering the market.

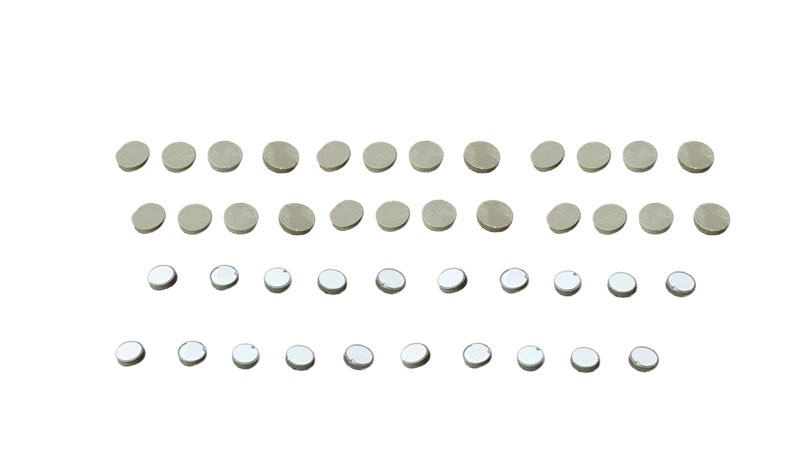

Sorting and classification: According to the test results, the products are divided into qualified and unqualified products, and the unqualified products are automatically removed or classified.

Image recording and analysis: Record image data during inspection, perform data analysis, statistics and generate reports in order to trace and optimize the production process.

Real-time monitoring and alarm: real-time monitoring of product status in the production process, timely detection of abnormal situations and trigger alarms to prevent further production of defective products.

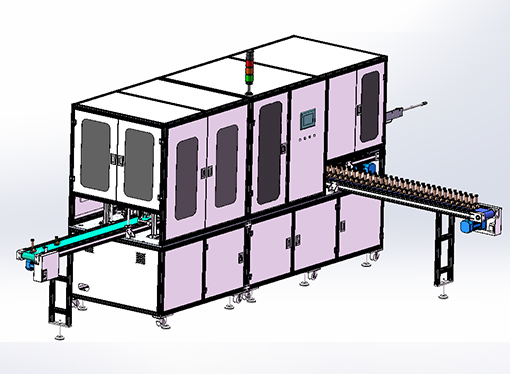

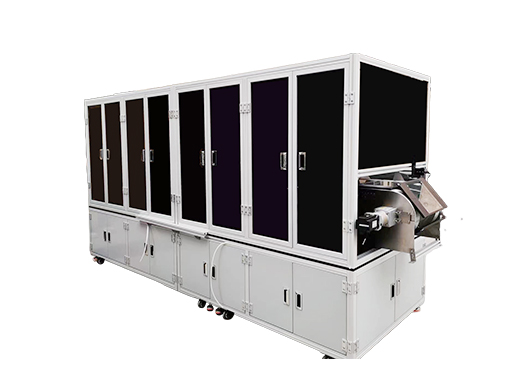

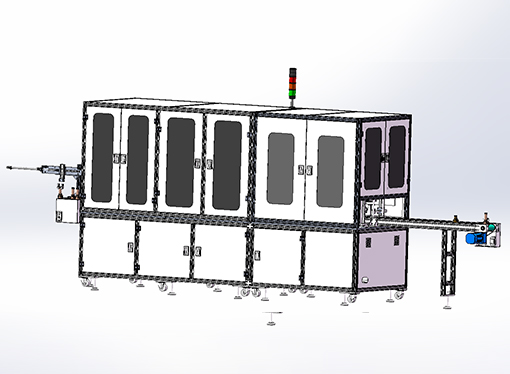

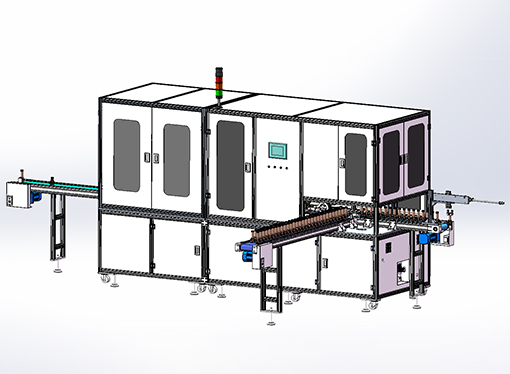

Device type | Pipeline tester |

Scope of application | It is suitable for the detection of rubber parts, precision hardware parts, automobile, mobile phone parts, plastic parts, electronic parts and other high-precision products. |

Optical system | Germany high rate CCD industrial camera, Japan imported lens, professional light source system |

Number of cameras | Standard 1 (can be configured according to demand) |

Control system | Germany Siemens Industrial Computer |

Image detection software | Siptech Vision inspection System |

Feed system | Conveyor belt |

Detection speed | 60 ~ 300 PCS/min (depending on product size) |

Recommended inspection size | 30 ~ 200mm |

Detection quality | 5 ~ 500g |

precision | Up to ±0.01mm |

Detection index | Detection of missing, misloading, mixing, defect detection, size detection, screen printing detection, etc |

Supply voltage | Two-phase 220V, 50Hz |

Rated power | 1kW |

Atmospheric pressure | The air pressure is not less than 0.35 ~ 0.7MPa |

Equipment weight | Approx. 150kg |

Operating temperature | -3 ° C to 45 ° C |

Storage temperature | -20℃ ~ 60℃ |

Equipment size | 1900mm(L)×500mm(W)×1300mm(H) |