Cloud disk high-speed visual inspection equipmentBack

Product description:Cloud disk high-speed vision inspection equipment is a combination of cloud computing and high-speed vision inspection technology equipment,

Product description:Cloud disk high-speed vision inspection equipment is a combination of cloud computing and high-speed vision inspection technology equipment,

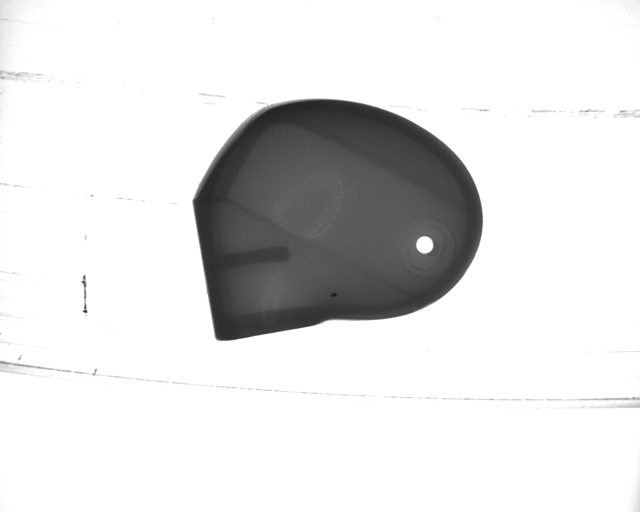

Cloud Disk high-speed visual inspection equipment is a device that combines cloud computing and high-speed visual inspection technology to quickly and accurately detect and analyze the appearance defects, features or attributes of the surface of an object. By connecting to a cloud server or cloud platform, the device uses cloud computing resources to accelerate the processing of image data for more efficient visual inspection and analysis.

Fast acquisition: The high-speed visual inspection system can quickly acquire a large number of image data to adapt to the detection needs of fast production lines.

Real-time processing: The high-speed vision inspection system has fast image processing capability and can process and analyze the acquired image data in real time.

High-speed recognition: high-speed visual inspection system can quickly identify product features, defects, etc., to achieve fast and accurate detection.

High frame rate: High-speed visual inspection systems usually have a high frame rate image acquisition function, which can capture images of fast moving objects.

Fast positioning: The high-speed visual inspection system can quickly and accurately locate the position of products or objects to achieve an efficient inspection process.

Automatic control: high-speed visual inspection systems usually have automatic control functions, which can automatically trigger detection, classification and other operations.

Efficient feedback: The high-speed visual inspection system can quickly feedback the test results, find problems in time and take countermeasures.

High accuracy: Despite the speed, the high-speed vision inspection system also maintains high accuracy characteristics, ensuring accurate inspection results.

Adapt to complex environment: high-speed visual inspection system can adapt to complex production environment, such as light changes, high-speed movement and so on.

Cloud disk high-speed vision inspection equipment has fast processing capabilities, and can analyze and detect a large amount of image data in a short time.

The device is connected to the cloud server or platform through the Internet to achieve remote monitoring, data storage, and analysis, improving the flexibility and scalability of the device. The advanced image processing algorithm can process the acquired images efficiently, extract features and identify defects. With automated inspection function, it can automatically identify and report defects or anomalies on the surface of objects.

Through the cloud connection, devices can upload detected data to the cloud for analysis and management, realizing real-time monitoring and traceability of data. Through continuous learning and optimization of the algorithm, the detection accuracy and efficiency can be improved to adapt to different detection needs.

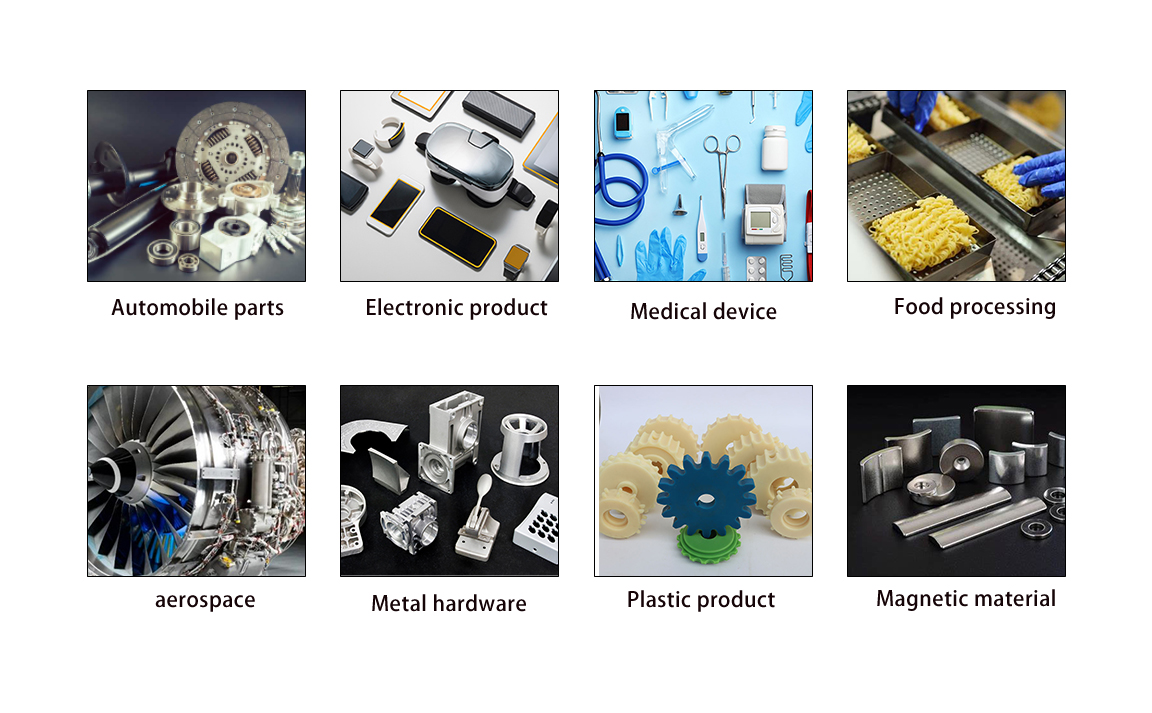

The equipment is widely used in electronic product manufacturing, auto parts production, medical equipment and other fields to help enterprises improve production quality and reduce costs.

Humanized design of the machine and system, simple operation mode, friendly user interface. Quickly complete the detection indicators, can detect up to 200 ~ 1200 per minute. No other damage will be caused to the product during the testing process.

Visual inspection software

Industrial computer

display

Industrial camera

Camera adjustment module

Industrial lens

illuminant

Detection platform

Servo motor

Visual inspection control system

PLC motion collaboration

Device type | High speed cloud disk tester (Glass disk) |

Scope of application | Suitable for testing screw products that can be placed smoothly. |

turntable | Special ring glass turntable |

Optical system | Germany high rate CCD industrial camera, Japan imported lens, professional light source system |

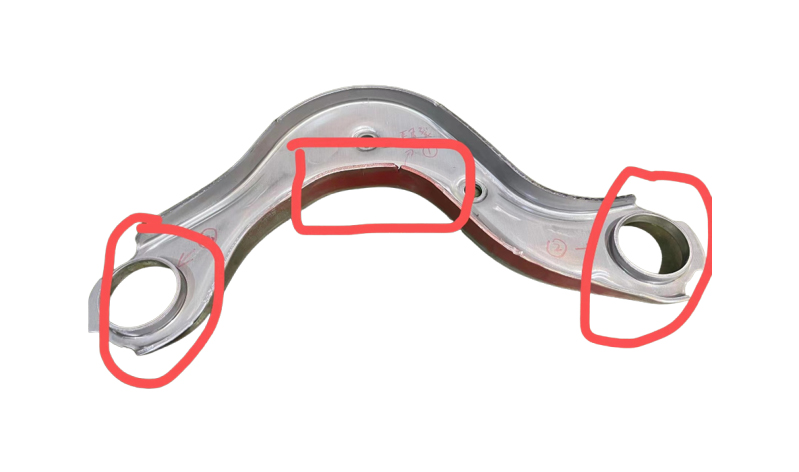

Number of cameras | Three are standard |

Control system | Industrial computer |

Image detection software | Siptech Vision inspection System |

Feed system | Special feed guide rail, a set of vibration disk equipment, automatic feed storage hopper equipment (optional) |

Packaging system | Automatic counting and packing machine (optional) |

Detection speed | 200 to 1200 PCS/min |

precision | Up to ±0.01mm |

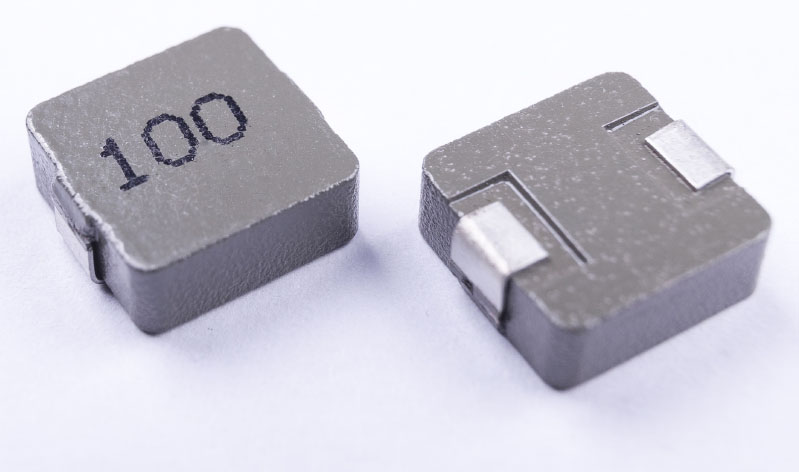

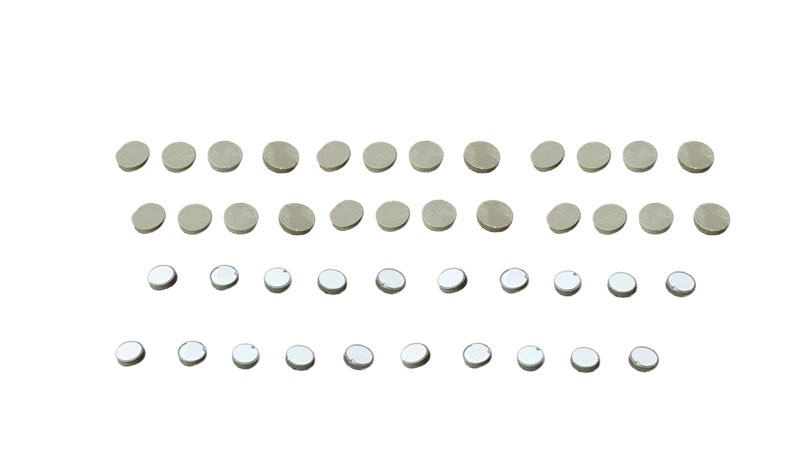

Recommended inspection size | 2 ~ 15mm |

Detection quality | 0.1 to 100g |

Detection index | Appearance size detection: screw bottom shape, screw head shape, screw inner and outer diameter, tooth distance, tooth Angle, step height, head height, etc |

Defect detection: 360-degree, there are no teeth, oblique teeth, bad rubbing teeth, burrs, solder joint area, marks, there are no internal teeth, all functions of standing flat head screw tooth parts can be detected | |

Supply voltage | Two-phase 220V, 50Hz |

Rated power | 1kW |

Atmospheric pressure | The air pressure is not less than 0.35 ~ 0.7MPa |

Equipment weight | About 500kg |

Operating temperature | -3 ° C to 45 ° C |

Storage temperature | -20℃ ~ 60℃ |

Equipment size | 1000mm(L)×1000mm(W)×1800mm(H) |

It is suitable for testing fasteners such as screws, nuts, lathe parts, stamping parts, injection parts, cold heading parts and fasteners that can be placed smoothly.

Service hotline