Embedded vision inspection devices are small devices with integrated vision inspection functions that are embedded in production equipment, robots, automation systems or other equipment for real-time inspection, analysis and control.

Real-time image acquisition: Embedded visual inspection equipment can collect image data in the environment in real time.

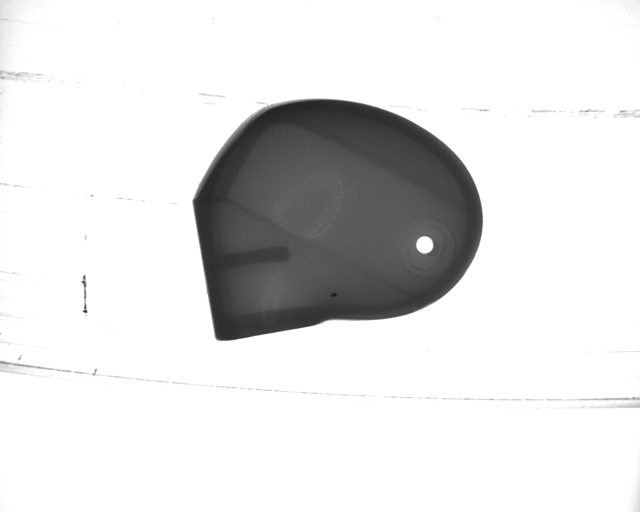

Image processing and analysis: image processing and analysis, including edge detection, feature extraction, target recognition, etc.

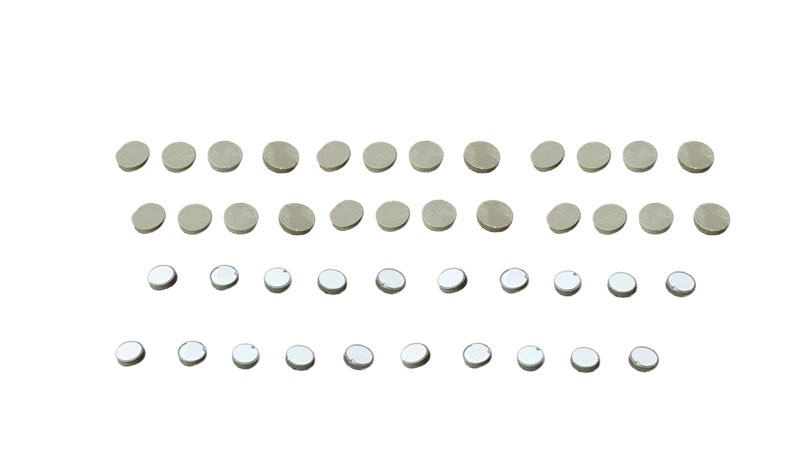

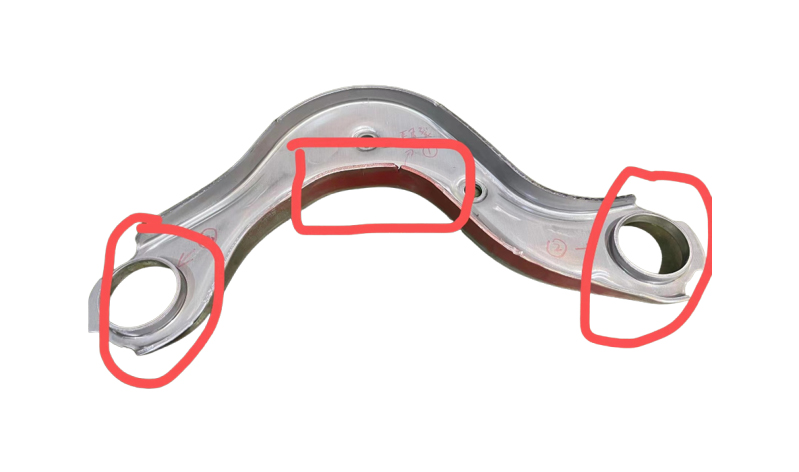

Object recognition: Identifying and classifying different objects or targets in an image can be used for automated control and production line detection.

Size measurement: The measurement and analysis of the size of the object to ensure that the product meets the specified size standards.

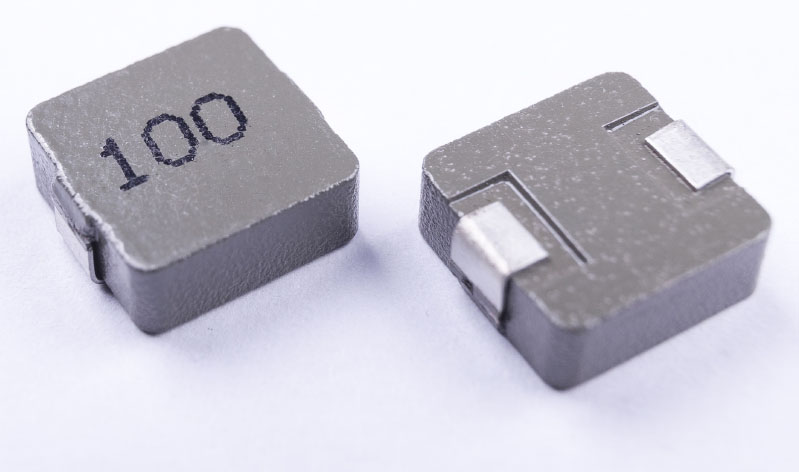

Defect detection: Detect defects or defects on the surface of the product, such as cracks, scratches, dents, etc., to help improve product quality.

Barcode/QR code scanning: Barcodes or QR codes can be scanned and analyzed for product traceability and data recording.

Real-time feedback and control: Provide real-time feedback of test results, and integrate with the control system to achieve real-time control and adjustment.

Automatic decision: Based on visual inspection results, automatic decision, such as quality determination, product classification, etc.

Data recording and analysis: Recording and analyzing inspection data, generating reports and providing statistical information to assist in quality management and process optimization.

Communication and networking: Support a variety of communication interfaces, data exchange and communication with other devices or systems, to achieve networking functions.

Self-learning ability: Some embedded vision inspection equipment has machine learning ability, which can continuously optimize algorithms and improve detection accuracy.

Miniaturization: Small size, light weight, easy to embed in a variety of devices.

Real-time: with fast image processing and analysis capabilities, real-time detection and feedback can be carried out.

Flexibility: It can be customized and integrated according to needs to adapt to different application scenarios.

Low power consumption: Usually with a low power design, suitable for long running and embedded system integration.

Automation: Support automated control and feedback to improve production efficiency and quality control.

High efficiency: real-time image processing and analysis to improve production efficiency and work efficiency.

Accuracy: High-precision detection and analysis through visual inspection technology.

Automation: Support automated control, reduce human intervention and error.

Data recording: Embedded visual inspection equipment is usually able to record inspection data for subsequent analysis and traceability.

Equipment size: 900*900*1750 mm

Power: 350W

Power supply range: AC22010%, 50Hz.

Operating environment temperature: 20-25 degrees

Operating environment humidity: 50%-70%

Measure CT= 10-15 seconds per piece

Repeatability: 0.015mm

Correlation: 0.018mm

Maximum range of XYZ: 400*400* 10mm z adjustable range of 150 mm

Fit plane of measurement values

Device type | Pipeline tester |

Scope of application | It is suitable for the detection of rubber parts, precision hardware parts, automobile, mobile phone parts, plastic parts, electronic parts and other high-precision products. |

Optical system | Germany high rate CCD industrial camera, Japan imported lens, professional light source system |

Number of cameras | Standard 1 (can be configured according to demand) |

Control system | Germany Siemens Industrial Computer |

Image detection software | Siptech Vision inspection System |

Feed system | Conveyor belt |

Detection speed | 60 ~ 300 PCS/min (depending on product size) |

Recommended inspection size | 30 ~ 200mm |

Detection quality | 5 ~ 500g |

precision | Up to ±0.01mm |

Detection index | Detection of missing, misloading, mixing, defect detection, size detection, screen printing detection, etc |

Supply voltage | Two-phase 220V, 50Hz |

Rated power | 1kW |

Atmospheric pressure | The air pressure is not less than 0.35 ~ 0.7MPa |

Equipment weight | Approx. 150kg |

Operating temperature | -3 ° C to 45 ° C |

Storage temperature | -20℃ ~ 60℃ |

Equipment size | 1900mm(L)×500mm(W)×1300mm(H) |