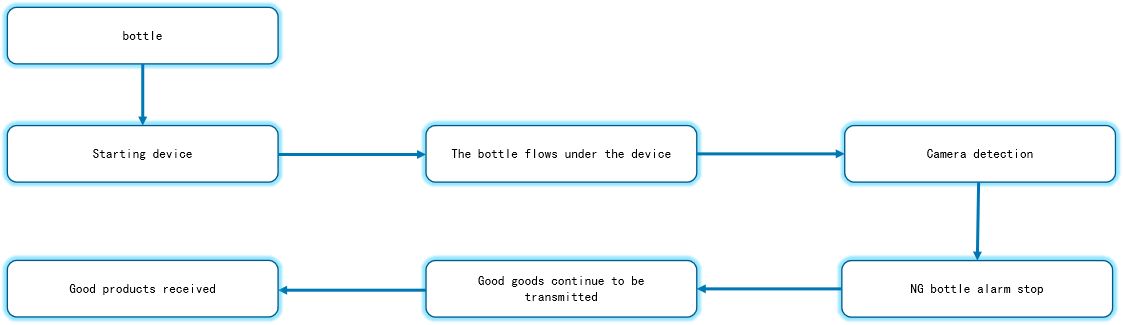

on-line Visual inspection technology that integrates image processing and intelligent algorithms to automatically detect and analyze product quality and characteristics on the production line. Improve production efficiency and reduce costs. Special pipeline online detection of error and missing loading, lack of materials and other bad detection platform. Humanized design of the machine and system, simple operation mode, friendly user interface. Quickly complete the test indicators.

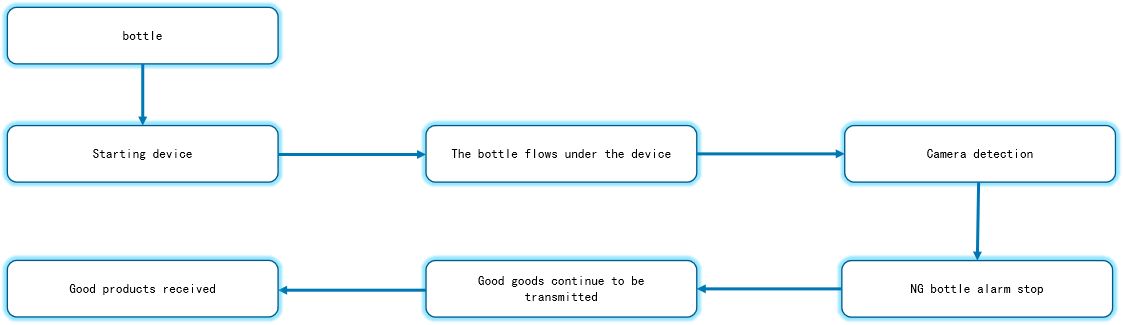

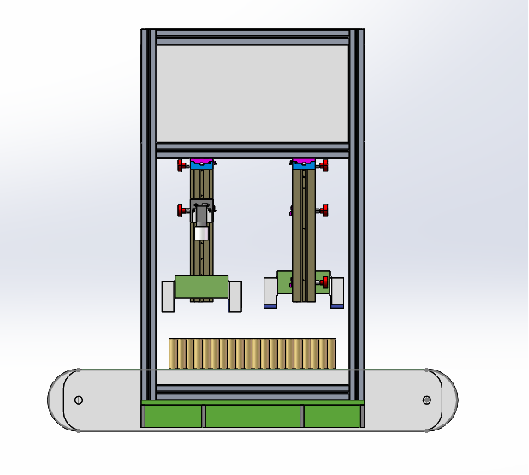

Automated inspection: The equipment can realize automated inspection without manual intervention, improving production efficiency and accuracy.

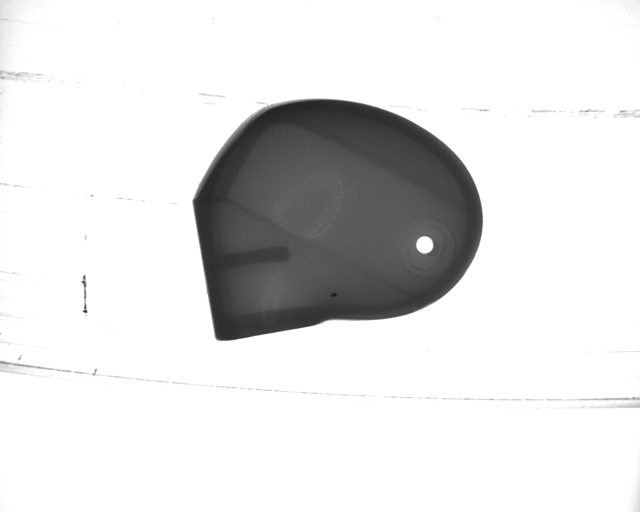

High-speed acquisition: The device has a fast image acquisition function, which can quickly capture product images on the pipeline.

Real-time processing: The device has real-time image processing capabilities, which can quickly analyze image data and make judgments.

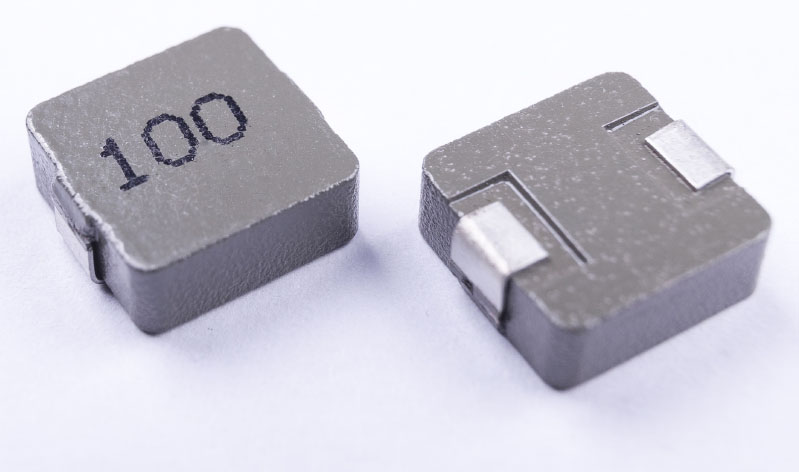

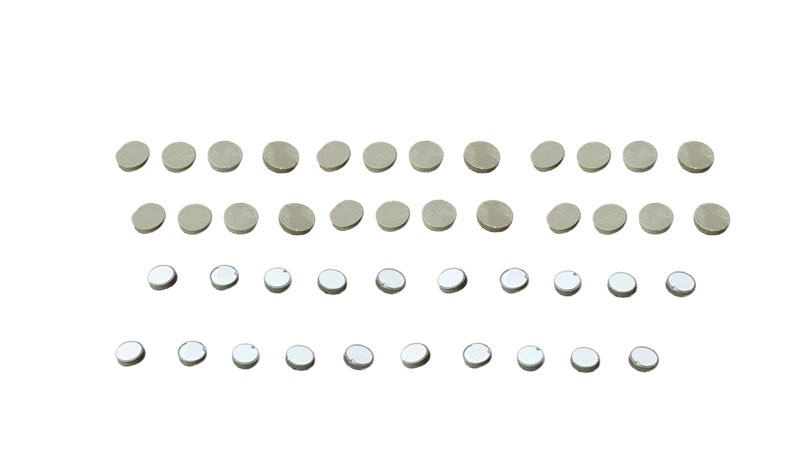

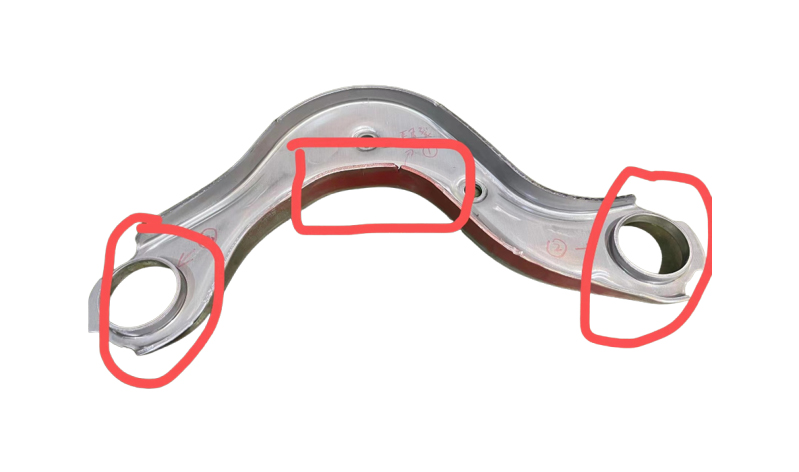

Defect detection: Detect defects, foreign bodies, damage and other problems on the surface of the product.

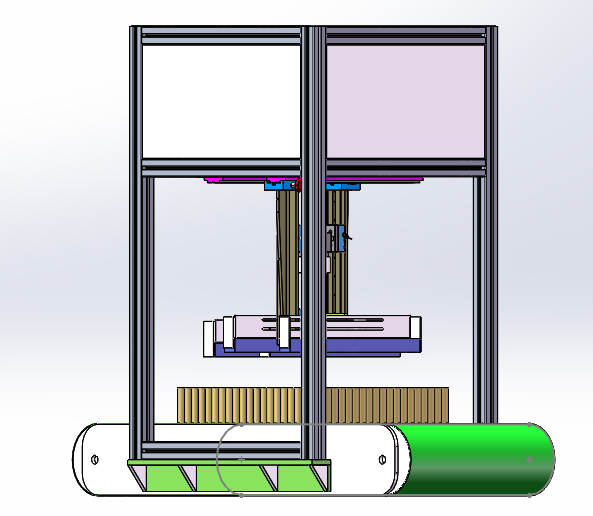

Size measurement: The device can measure product size, shape and other parameters.

Classification and sorting: The product is classified and sorted according to the test results.

Data recording and reporting: The equipment can record inspection data and generate reports to facilitate quality management and traceability.

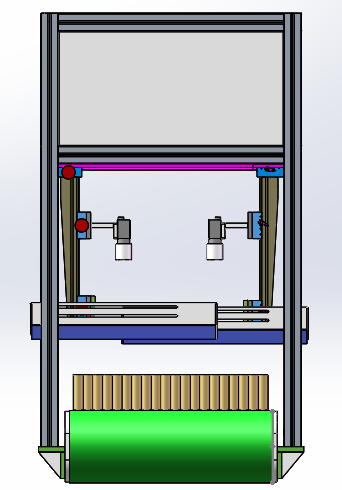

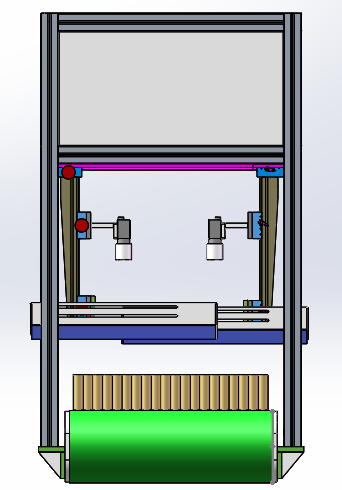

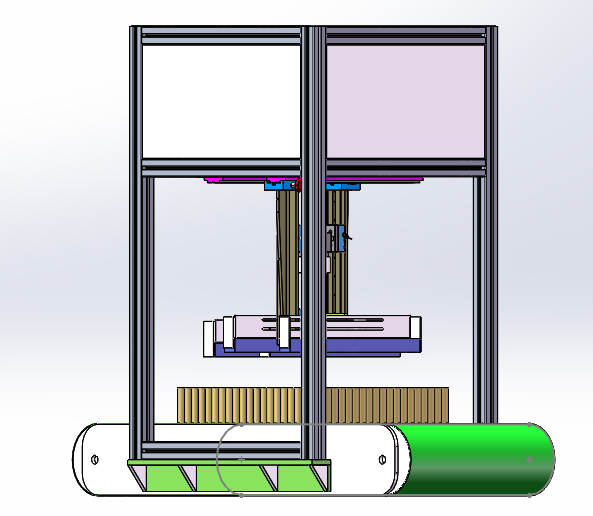

Multi-view detection: Support multi-view detection, obtain image data from different angles, improve the comprehensiveness of detection.

Real-time feedback: Real-time feedback of test results, timely detection of problems and feedback to help adjust the production process.

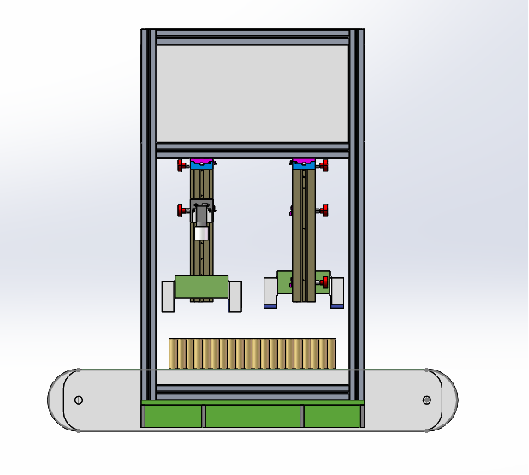

1. The size of the equipment is about length * width * height =59mm*590m*1053mm (excluding the original height of the customer assembly line);

2. The equipment is safe to operate and equipped with an emergency stop button;

Using the LCD touch screen display interface, the device mechanism can display alarm and fault warning lifting measures.

The main control has emergency stop, stop, start, inch and other buttons.

Pneumatic components: SMC\AIRTAC\KGN\ARK, etc

Hardware: MISUMI, etc

Laser module: custom development

Thermal imaging modules: custom development

Input power: AC 220V 50/60HZ; 5-6kg/cm2 clean pressure air.

Device type | Pipeline tester

|

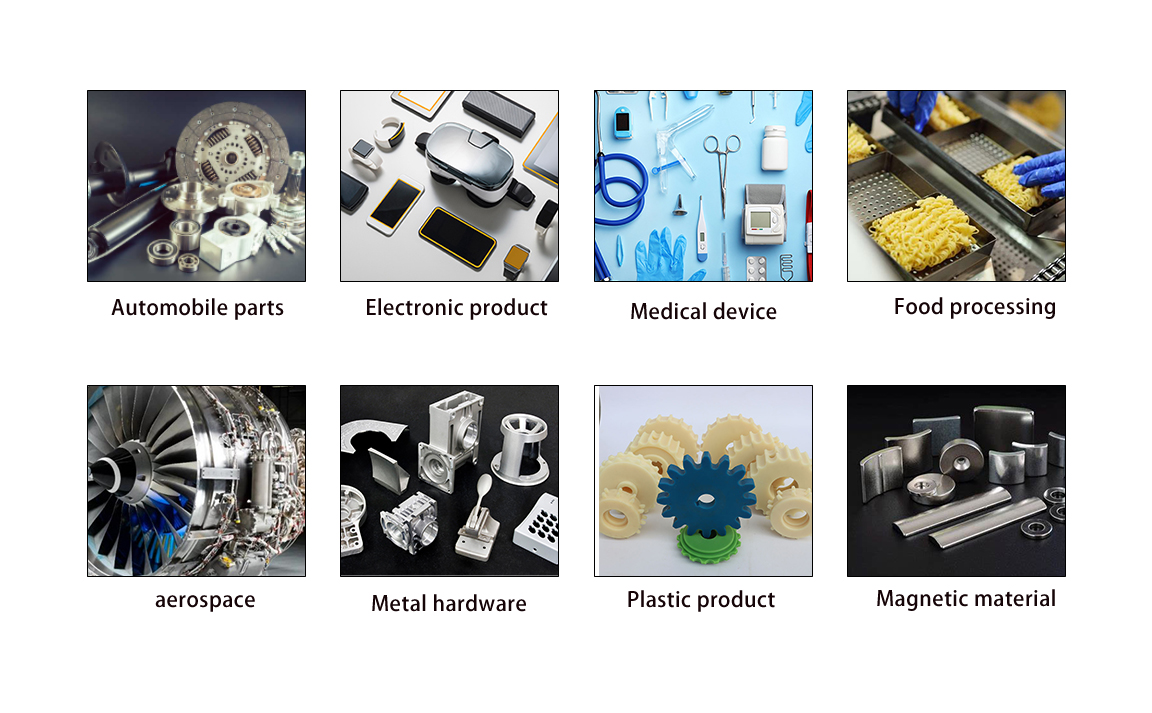

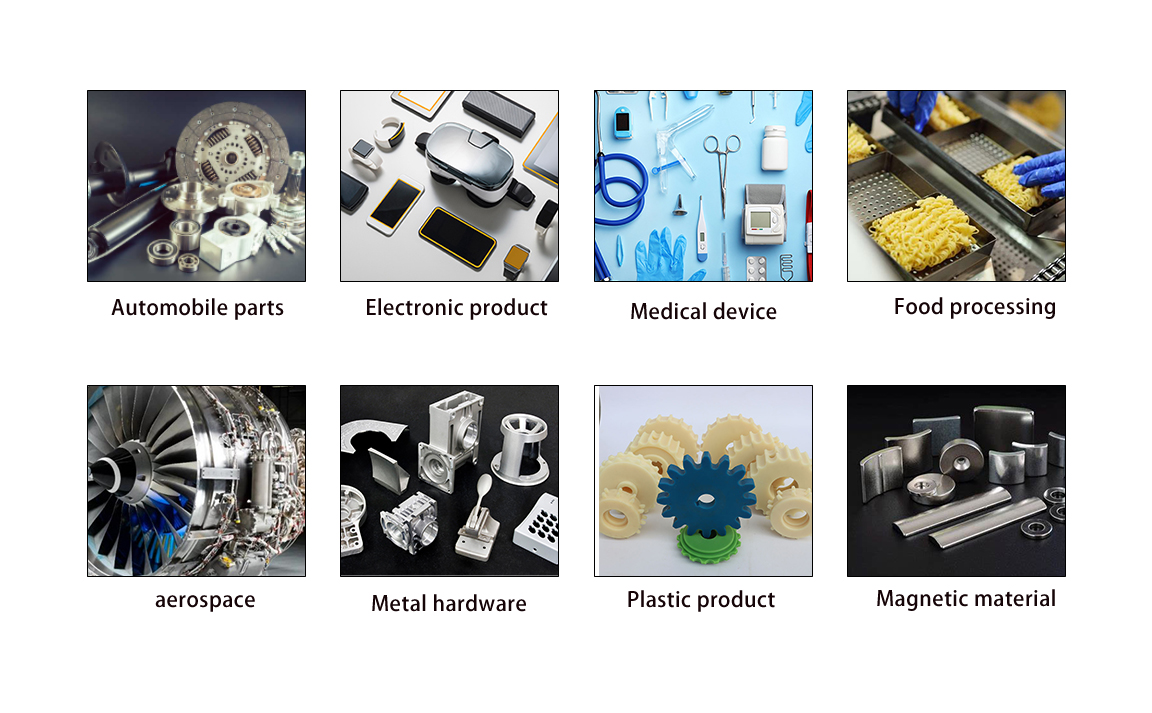

Scope of application |

It is suitable for the detection of rubber parts, precision hardware parts, automobile, mobile phone parts, plastic parts, electronic parts and other high-precision products. |

Optical system |

Germany high rate CCD industrial camera, Japan imported lens, professional light source system |

Number of cameras |

Standard 1 (can be configured according to demand) |

Control system |

Germany Siemens Industrial Computer |

Image detection software |

Siptech Vision inspection System |

Feed system |

Conveyor belt |

Detection speed |

60 ~ 300 PCS/min (depending on product size) |

Recommended inspection size |

30 ~ 200mm |

Detection quality |

5 ~ 500g |

precision |

Up to ±0.01mm |

Detection index |

Detection of missing, misloading, mixing, defect detection, size detection, screen printing detection, etc |

Supply voltage |

Two-phase 220V, 50Hz |

Rated power |

1kW |

Atmospheric pressure |

The air pressure is not less than 0.35 ~ 0.7MPa |

Equipment weight |

Approx. 150kg |

Operating temperature |

-3 ° C to 45 ° C |

Storage temperature |

-20℃ ~ 60℃ |

Equipment size |

1900mm(L)×500mm(W)×1300mm(H) |

It is suitable for the detection of rubber parts, precision hardware parts, automobile, mobile phone parts, plastic parts, electronic parts and other high-precision products.