Industrial machine vision systems integrate highly packaged visual algorithm tools including positioning, defect detection, code recognition, geometric measurement and other functions. Users do not need to write programs, only need simple configuration guidance to complete a variety of visual solutions.

1: SONY Industrial Vision host (including power supply, power cord)

2: Philips display 19 inches

3: Wireless keyboard, mouse, WIFI receiver

4: SONY (1.6 megapixel) Industrial camera (including cable)

5:25mm FA lens

6: 7060 white ring light source (including 1 meter extension cord)

7: Adjustable light source controller

Handling assembly guidance: visual positioning

Production online process testing: there is no assembly, mixed classification identification

Packaging online detection: missing packaging identification, counting detection

Printed label detection: identification reading

Product traceability record: product barcode or two-dimensional code identification follow

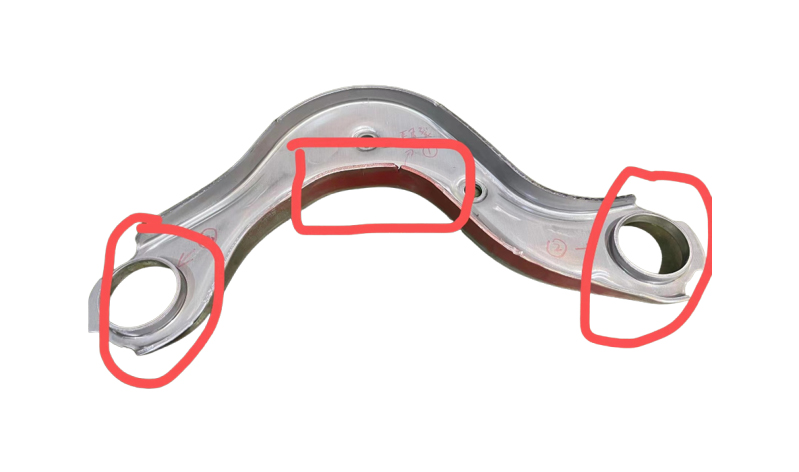

Online real-time quality control: appearance inspection, size measurement

Positioning guide: contour graphics, edge, Angle, center positioning

Classification recognition: pattern recognition, contour recognition, whether or not recognition

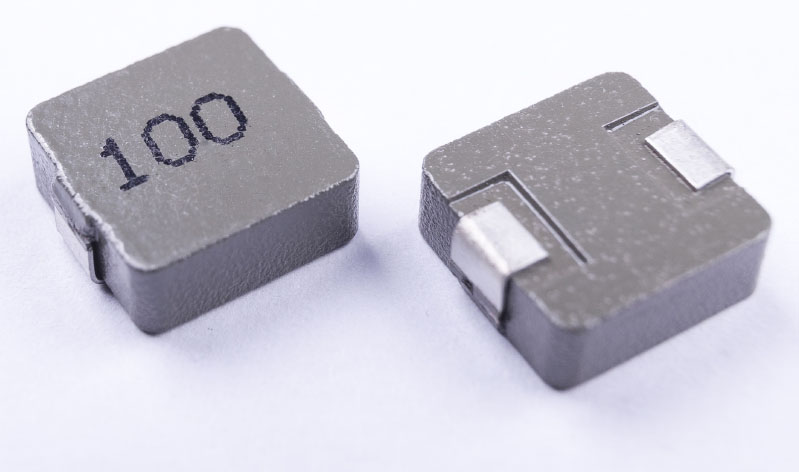

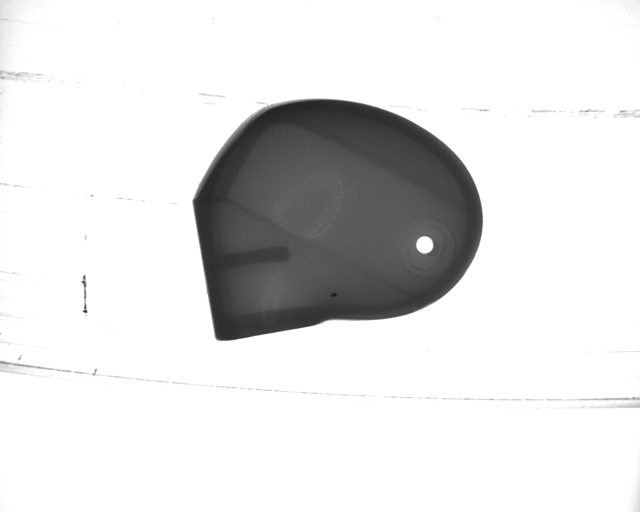

Appearance inspection: defects, defects, stains

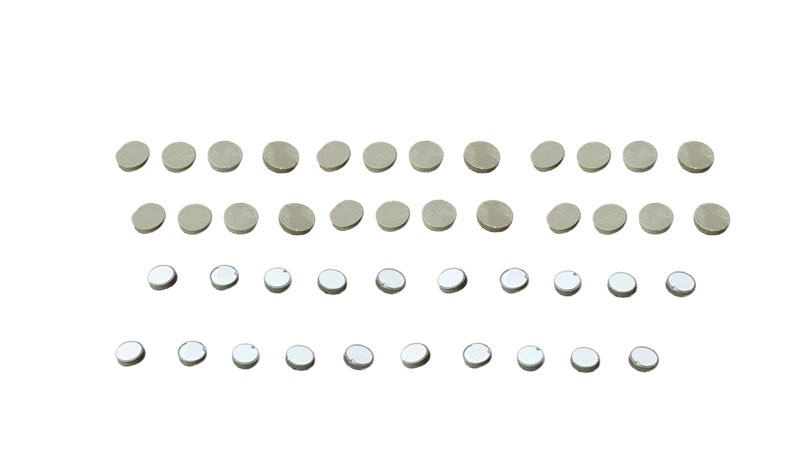

Visual points: contour count, block count, figure count

Identification reading: bar code, two-dimensional code

Geometric measurement: Measuring length, width, circle, point, line, Angle, radian

Printing detection: printing errors, omissions, ink

Character recognition: recognition of English and numbers

Device type | SONY Industrial Vision System |

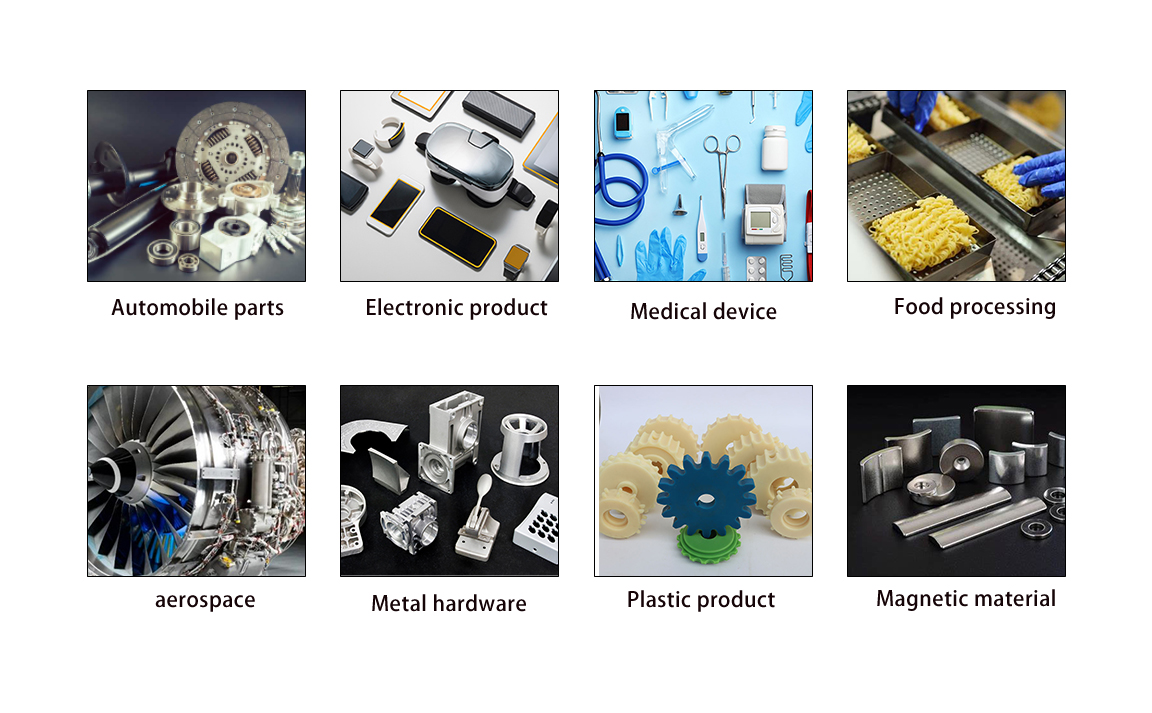

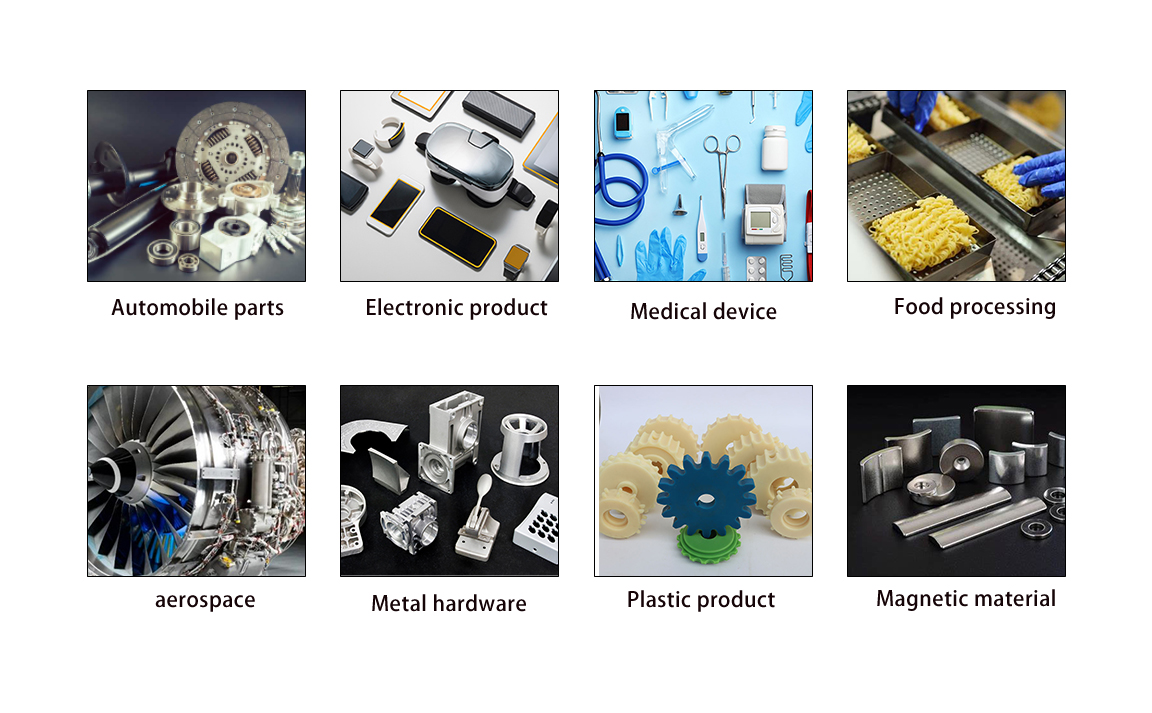

Scope of application | It is suitable for testing hardware, injection molding, automobile, 3C, food, medicine, robot and other industries. |

Optical system | SONY industrial camera, Japanese imported lens, professional light source system |

Number of cameras | 1 as standard (up to 4 can be configured according to demand) |

Image detection software | Siptech Vision inspection System |

Detection speed | Image processing speed 50ms |

precision | Up to ±0.005mm |

Detection index | Size measurement, appearance detection, character recognition, printing detection, bar code detection, classification recognition, positioning guidance, counting statistics |

Supply voltage | Ac 220V, 50Hz |

Rated power | 1kW |

Equipment weight | About 5kg |

Operating temperature | -3 ° C to 45 ° C |

Storage temperature | -20℃ ~ 60℃ |

Equipment size | 350mm(L)×250mm(W)×75mm(H) |

It is suitable for testing hardware, injection molding, automobile, 3C, food, medicine, robot and other industries.

The machine vision inspection system integrates highly packaged vision algorithm tools including positioning, defect detection, code recognition, geometric measurement and other functions. Users do not need to write programs, just a simple configuration guide to complete a variety of visual schemes.