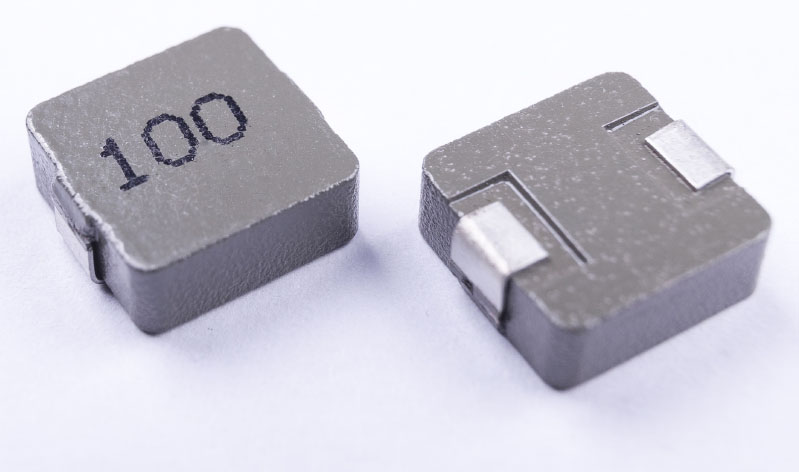

Hardware visual inspection uses a high-resolution camera to capture the image of hardware products, and then identifies and analyzes the features in the image through image processing algorithms to detect defects, size, shape, color, etc. Through hardware visual inspection, reduce human error, reduce the rate of unqualified products, improve production efficiency, save labor costs, improve product quality and customer satisfaction.

Equipment features: 12 sets of 5 million camera lenses work at the same time

Main functions: Detection of mobile phone Cato/precision hardware full size

Detection accuracy: The detection size is accurate up to 0.007mm

Professional fixture: Customized fixture loading for different cato

Detection speed: about 4000pcs/h

Can detect glass/stainless steel/aluminum and other materials

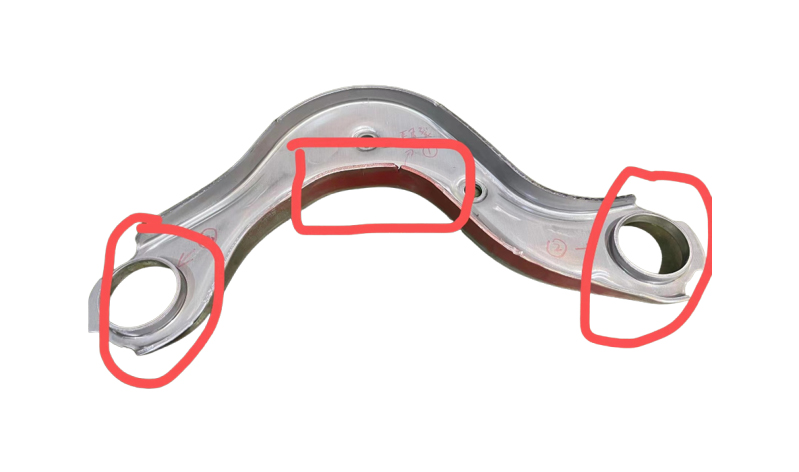

Defect detection: Detect defects on the surface of hardware products, such as scratches, dents, bubbles, deformation, etc.

Size measurement: Measuring the size and geometry of hardware products, including length, width, diameter, etc.

Positioning detection: accurate positioning of various components or components on hardware products to ensure the accuracy of assembly.

Missing parts detection: Detecting whether there are missing parts or components in hardware products.

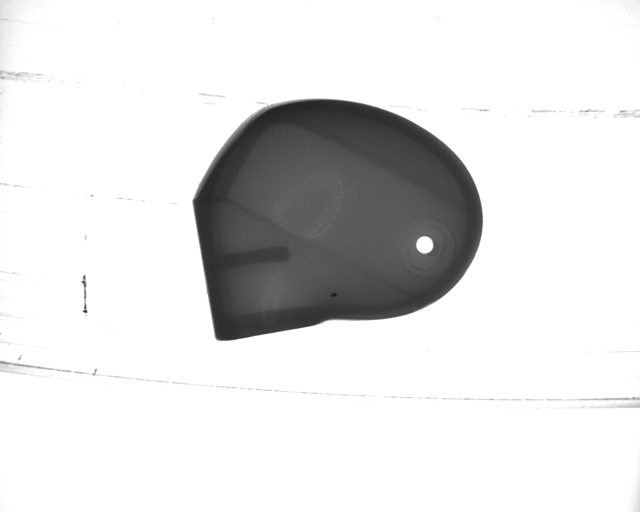

Foreign body detection: Detect whether there are foreign bodies or impurities on the surface of hardware products to ensure the purity of the product.

Color detection: Detect whether the color of hardware products meets the requirements to avoid color difference problems.

Edge detection: Detect whether the edge of hardware products is smooth and complete to avoid burrs or damage.

Surface quality inspection: detection of hardware products surface smoothness, gloss, surface treatment, etc. meet the standards.

Image acquisition and comparison: Collect the image data of hardware products, and compare it with the standard image to detect any non-conformity.

Real-time feedback and control: Provide real-time feedback of test results, and integrate with the production control system to achieve real-time control and adjustment.

Image acquisition: Using the camera to collect images on the surface of hardware products to obtain the appearance information of the target object.

Light source adjustment: Through the appropriate light source Settings, to ensure uniform lighting on the surface of hardware products, reduce the impact of reflection and shadow.

Image processing: The image processing software is used to process and analyze the acquired images to identify the surface defects, defects, scratches, etc.

Feature detection: Extract the features of hardware products, such as size, shape, surface finish, etc., for quantitative analysis.

Defect recognition: Detect and identify defects on the surface of hardware products through image processing algorithms, such as dents, cracks, bubbles, etc.

Quality assessment: Evaluate the quality of hardware products according to the test results to determine whether they meet the specified standards.

Result output: Output the test result to the control system to provide qualified or unqualified decision information for subsequent processing.

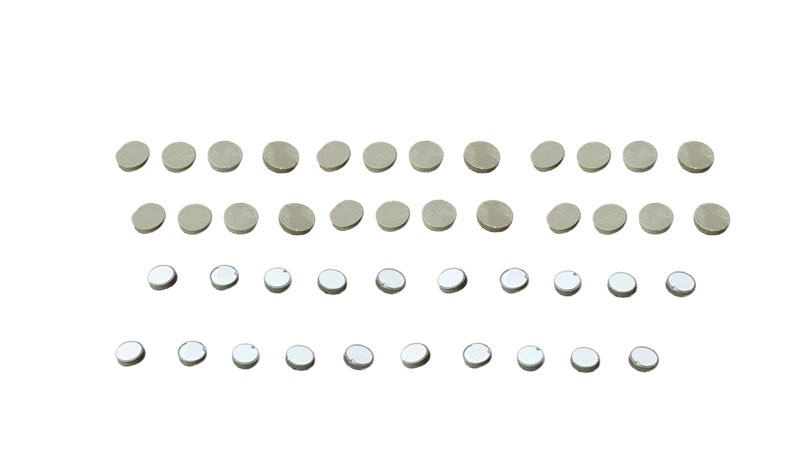

Device type | High speed cloud disk tester (Glass disk) |

Scope of application | Suitable for testing screw products that can be placed smoothly. |

turntable | Special ring glass turntable |

Optical system | Germany high rate CCD industrial camera, Japan imported lens, professional light source system |

Number of cameras | Three are standard |

Control system | Industrial computer |

Image detection software | Siptech Vision inspection System |

Feed system | Special feed guide rail, a set of vibration disk equipment, automatic feed storage hopper equipment (optional) |

Packaging system | Automatic counting and packing machine (optional) |

Detection speed | 200 to 1200 PCS/min |

precision | Up to ±0.01mm |

Recommended inspection size | 2 ~ 15mm |

Detection quality | 0.1 to 100g |

Detection index | Appearance size detection: screw bottom shape, screw head shape, screw inner and outer diameter, tooth distance, tooth Angle, step height, head height, etc |

Defect detection: 360-degree, there are no teeth, oblique teeth, bad rubbing teeth, burrs, solder joint area, marks, there are no internal teeth, all functions of standing flat head screw tooth parts can be detected |

Supply voltage | Two-phase 220V, 50Hz |

Rated power | 1kW |

Atmospheric pressure | The air pressure is not less than 0.35 ~ 0.7MPa |

Equipment weight | About 500kg |

Operating temperature | -3 ° C to 45 ° C |

Storage temperature | -20℃ ~ 60℃ |

Equipment size | 1000mm(L)×1000mm(W)×1800mm(H) |

Manufacturing: Used to test the quality control of hardware products in the production process to ensure that products meet the specified standards.

Automotive industry: It can be used to detect surface defects and dimensional deviations of auto parts.

Home decoration: used to detect the appearance quality and surface treatment effect of hardware accessories.

Construction industry: can be used to test the quality and reliability of hardware tools to ensure construction safety.

Hardware visual inspection equipment can help manufacturers improve product quality, improve production efficiency, reduce human error, and ensure that hardware products meet quality requirements in the manufacturing process.

Metal parts processing Metal surface treatment Hardware assembly