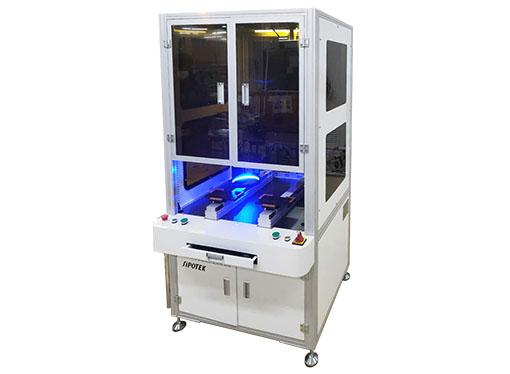

The XY axis vision inspection device is a vision inspection system capable of moving on two horizontal axes (X and Y) for high-precision positioning, measurement and inspection on a plane. Combining mechanical structure, camera, light source and image processing software, the target on the plane is located, tracked and analyzed.

Positioning detection: XY axis visual detection can accurately detect and locate the position of the target object on a two-dimensional plane.

Track tracking: Track the target object in the XY plane, and monitor the movement of the object.

Shape recognition: Identify and analyze the shape features of the target object on the XY plane, such as circle, rectangle, etc.

Size measurement: Size measurement on the XY plane to detect the length, width and other size information of the object.

Edge detection: Detect and extract the edge of the target object on the XY plane for shape analysis and positioning.

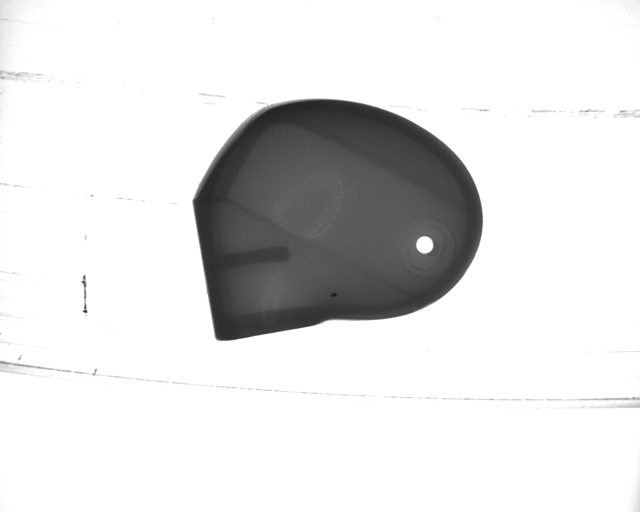

Image acquisition: The image data on the XY plane is collected for subsequent processing and analysis.

Axial calibration: The XY axis is calibrated to ensure the accuracy and stability of detection and positioning.

Real-time feedback and control: Provide real-time feedback of test results, and integrate with the control system to achieve real-time control and adjustment.

Automatic decision: Based on the XY axis visual detection results, automatic decision, such as target object classification, positioning, etc.

Data recording and analysis: Record and analyze XY axis visual inspection data, generate reports and provide statistical information for quality management and production optimization.

High precision positioning

XY axis motion system can achieve accurate two-dimensional positioning, combined with computer vision technology can achieve accurate positioning and detection of products, improve the detection accuracy.

Multi-angle detection

XY axis visual inspection equipment can detect products at different angles and positions, improving inspection comprehensiveness and accuracy.

High speed movement:

The XY axis system can achieve fast translation and positioning, combined with computer vision technology can achieve high-speed product inspection, suitable for high-speed production lines.

flexibility

XY axis visual inspection equipment can flexibly adjust the movement path and speed of XY axis, which is suitable for product inspection of different sizes and shapes.

High degree of automation

Combined with computer vision technology, XY axis vision inspection equipment can realize automated inspection and data processing, reduce manual intervention, and improve production efficiency.

versatility

XY axis visual inspection equipment can achieve a variety of functions, such as size measurement, defect detection, positioning recognition, etc., with strong applicability.

Real-time feedback:

XY axis visual inspection equipment can feedback the inspection results in real time, find problems in time and take measures to improve the response speed of the production line.

Data recording and analysis

The equipment can record large amounts of inspection data, analyze the data in combination with computer vision technology, and generate reports and statistics to help optimize the production process.

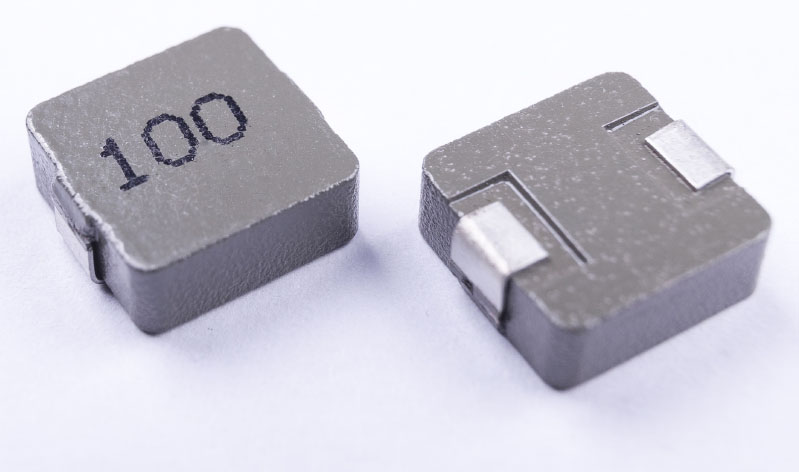

Device type | High speed cloud disk tester (Glass disk) |

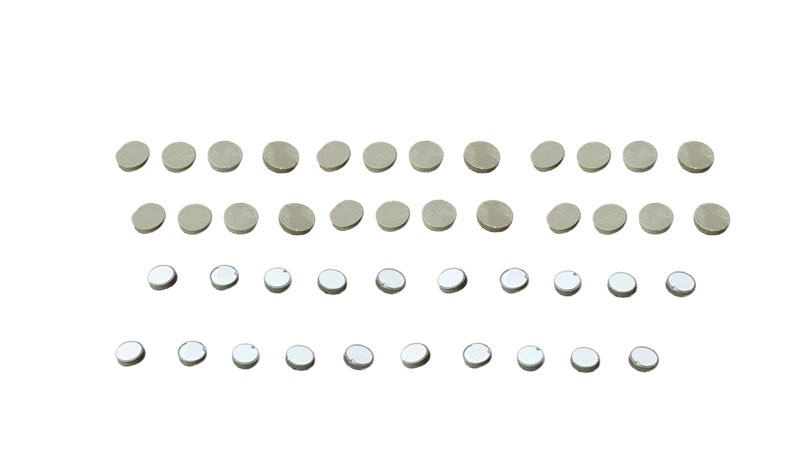

Scope of application | Suitable for testing screw products that can be placed smoothly. |

turntable | Special ring glass turntable |

Optical system | Germany high rate CCD industrial camera, Japan imported lens, professional light source system |

Number of cameras | Three are standard |

Control system | Industrial computer |

Image detection software | Siptech Vision inspection System |

Feed system | Special feed guide rail, a set of vibration disk equipment, automatic feed storage hopper equipment (optional) |

Packaging system | Automatic counting and packing machine (optional) |

Detection speed | 200 to 1200 PCS/min |

precision | Up to ±0.01mm |

Recommended inspection size | 2 ~ 15mm |

Detection quality | 0.1 to 100g |

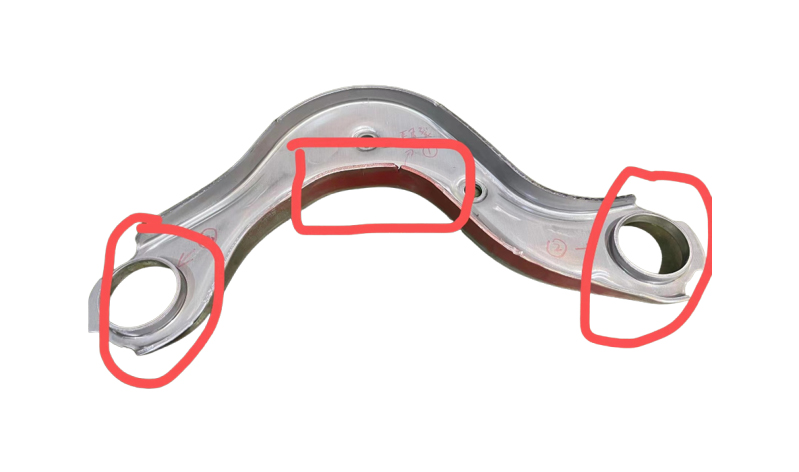

Detection index | Appearance size detection: screw bottom shape, screw head shape, screw inner and outer diameter, tooth distance, tooth Angle, step height, head height, etc |

Defect detection: 360-degree, there are no teeth, oblique teeth, bad rubbing teeth, burrs, solder joint area, marks, there are no internal teeth, all functions of standing flat head screw tooth parts can be detected |

Supply voltage | Two-phase 220V, 50Hz |

Rated power | 1kW |

Atmospheric pressure | The air pressure is not less than 0.35 ~ 0.7MPa |

Equipment weight | About 500kg |

Operating temperature | -3 ° C to 45 ° C |

Storage temperature | -20℃ ~ 60℃ |

Equipment size | 1000mm(L)×1000mm(W)×1800mm(H) |

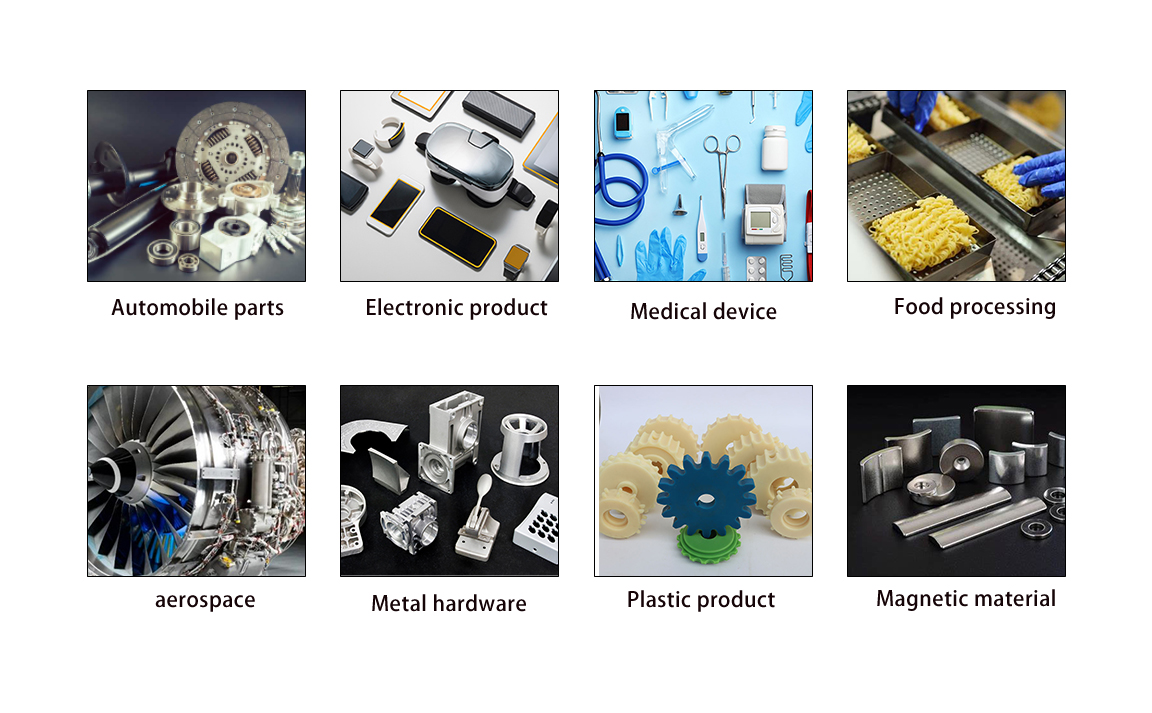

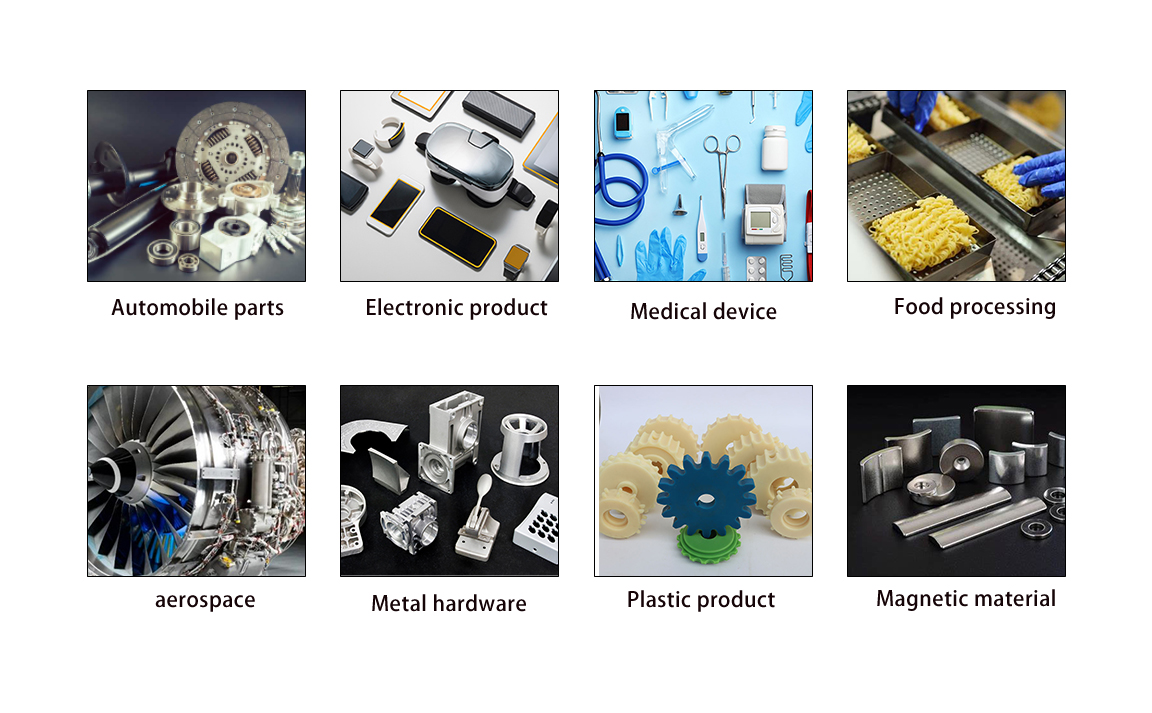

PCB production: used to detect the position of components on the circuit board, solder joint quality, etc.

Automated assembly: can be used for parts assembly and positioning.

Medical equipment: Used to test the component size and assembly quality of medical equipment.

Printing industry: Used to test typographical accuracy and color quality of printed matter.

XY axis visual inspection equipment plays an important role in industrial production, which can improve production efficiency, ensure product quality, and realize automated inspection and measurement processes.