The aoi Vision detector is a space-saving desktop model that completely replaces quadratic equipment. Multiple products can be measured at one time to achieve rapid detection. Arbitrary placement of products, simple operation without any fixture, positioning without moving platform, reduce human error. Continuous placement of work, press a key to complete the measurement of all items. The operation is simple and anyone can easily master it in three minutes.

Easy to use interface, users can complete the inspection process with one click. Integrated automated image processing algorithms that automatically identify, analyze and measure the size and shape of target objects. Rapid detection and analysis to improve production efficiency and quality control. It can be customized according to different application requirements and supports multiple detection tasks and parameter Settings. With high-precision measurement function, it can accurately measure the size and shape of the target object.

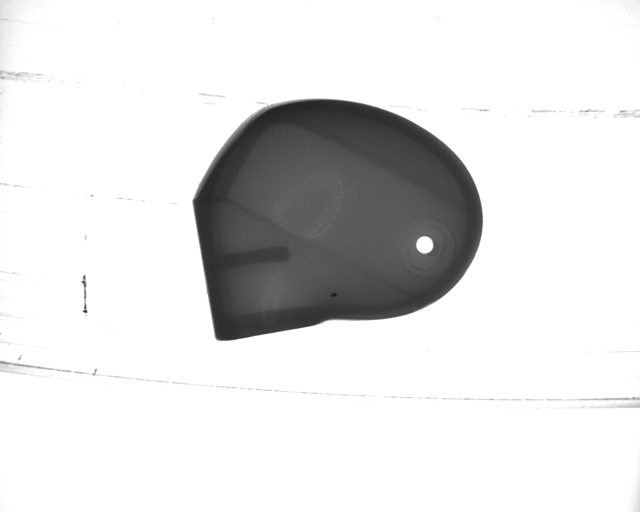

Image acquisition: high-resolution images can be acquired to provide clear image data for subsequent analysis and processing.

Image processing: The image processing algorithm is used to analyze the acquired images and identify product features and defects.

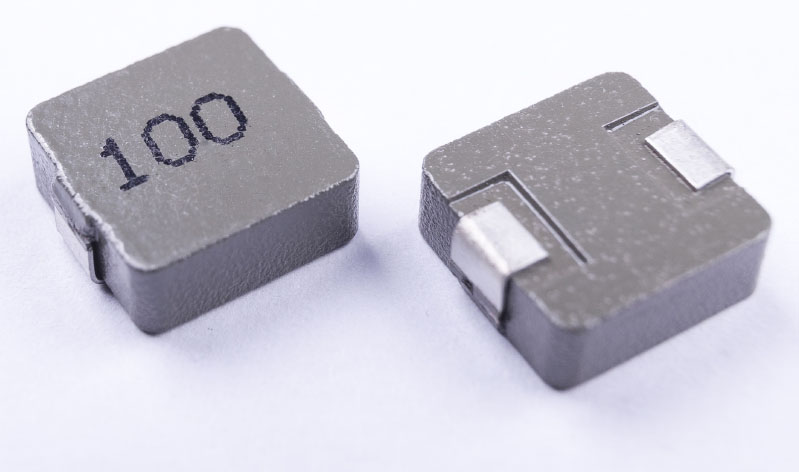

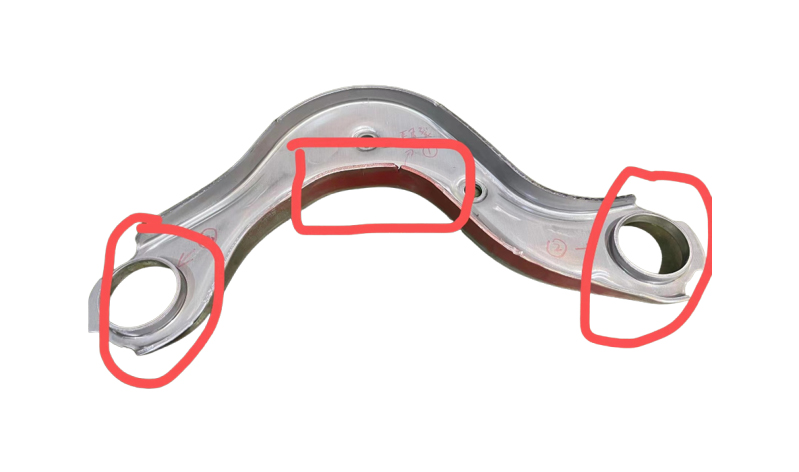

Defect detection: identify product surface defects, cracks, defects, dislocation, etc., and mark or classify them.

Size measurement: Measure the size, length, width and other parameters of the product to ensure that the product meets the specifications.

Color recognition: Identify the color of the product and detect whether it meets the preset standards or requirements.

Shape recognition: Identify the shape features of the product, round, square, etc., and perform shape matching or classification.

Positioning detection: helps locate the position of products or objects to ensure proper placement or assembly.

Automatic classification: According to the test results, the products are automatically classified to distinguish qualified products and unqualified products.

Data recording and analysis: record test results and data, conduct data analysis, report generation and other follow-up work.

1. Space saving desktop models

2. Fast speed, high efficiency, all sizes, only 2 seconds, to meet the requirements of batch testing. Greatly reduce measurement time.

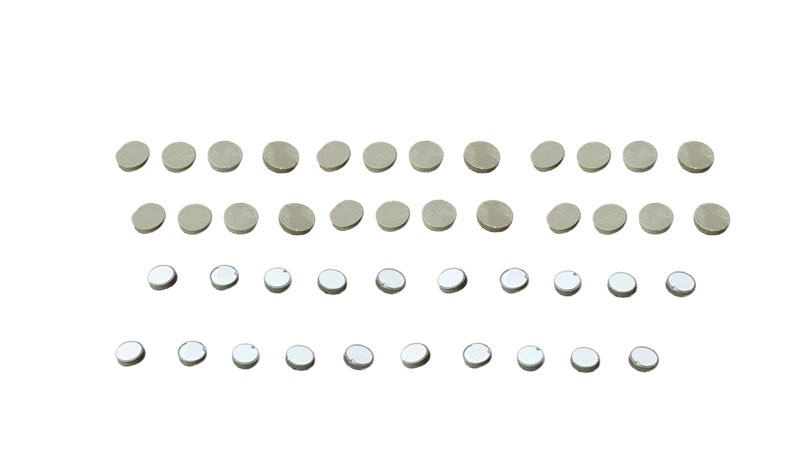

3. Multiple products can be measured at one time to achieve rapid detection (1 second), which can directly display good and bad products.

4. Arbitrary placement of products, simple operation without any fixture; Positioning without platform movement.

5. Reduce human error, the software automatically matches the template.

6. Even the casket placement work, the measurement of all items is completed with one click

7 Simple operation, anyone can easily master within three minutes.

1. Industrial cameras

High resolution industrial cameras. Capture an image of the target object.

2. Light Source

A light source is provided to ensure image clarity and quality. Can include LED lights, optical fiber light source, etc.

3. Image processing algorithm

The acquired images are processed and analyzed. It includes image filtering, edge detection, feature extraction and so on.

4. Visual inspection control system

Control the operation and parameter setting of the entire equipment. Embedded control system or computer software.

5. Display

The detection result and operation interface are displayed. Provide a user interface to manipulate and view results.

6. Data processing unit

The processed data is calculated, analyzed and stored. Include microprocessors, embedded systems, or computers.

7. User interface

Provides user-friendly operation interface, including buttons, touch screens, etc. The design is simple and intuitive, convenient for users to operate and set.

8. Mechanical structure

Support and secure components such as cameras and light sources. Including support, adjusting device, etc.

9. Power system

Provide power supply to the equipment. Including batteries, power adapters, etc.

Device type | One-button measuring platform |

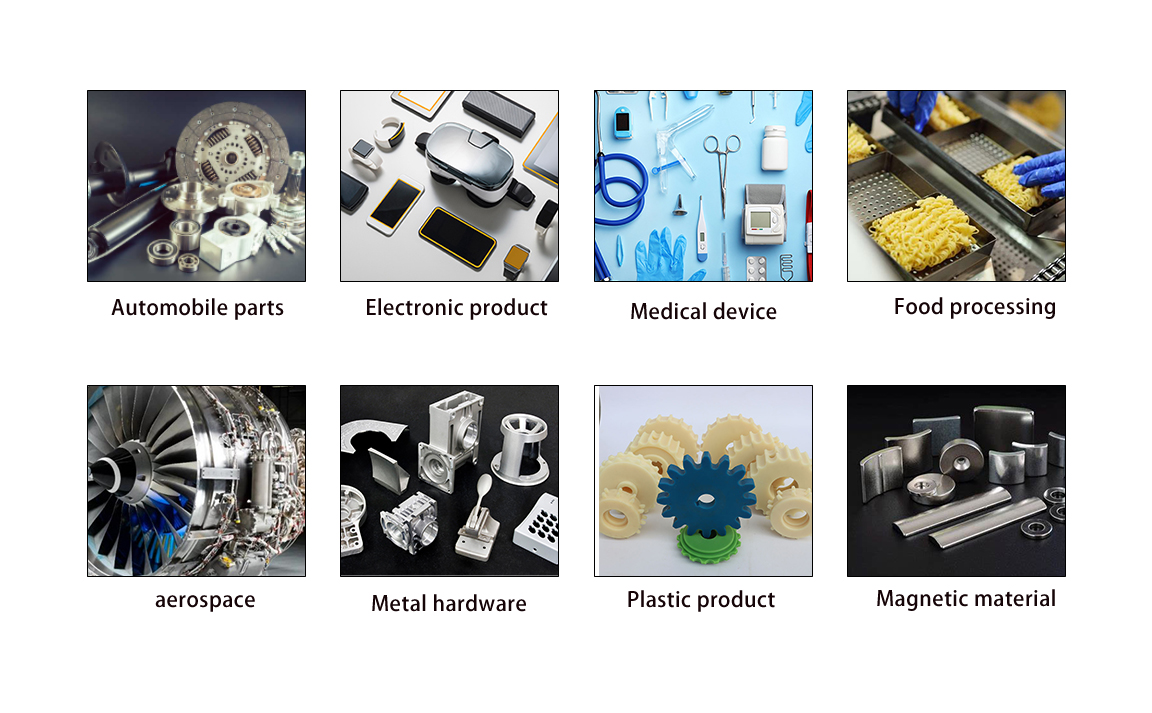

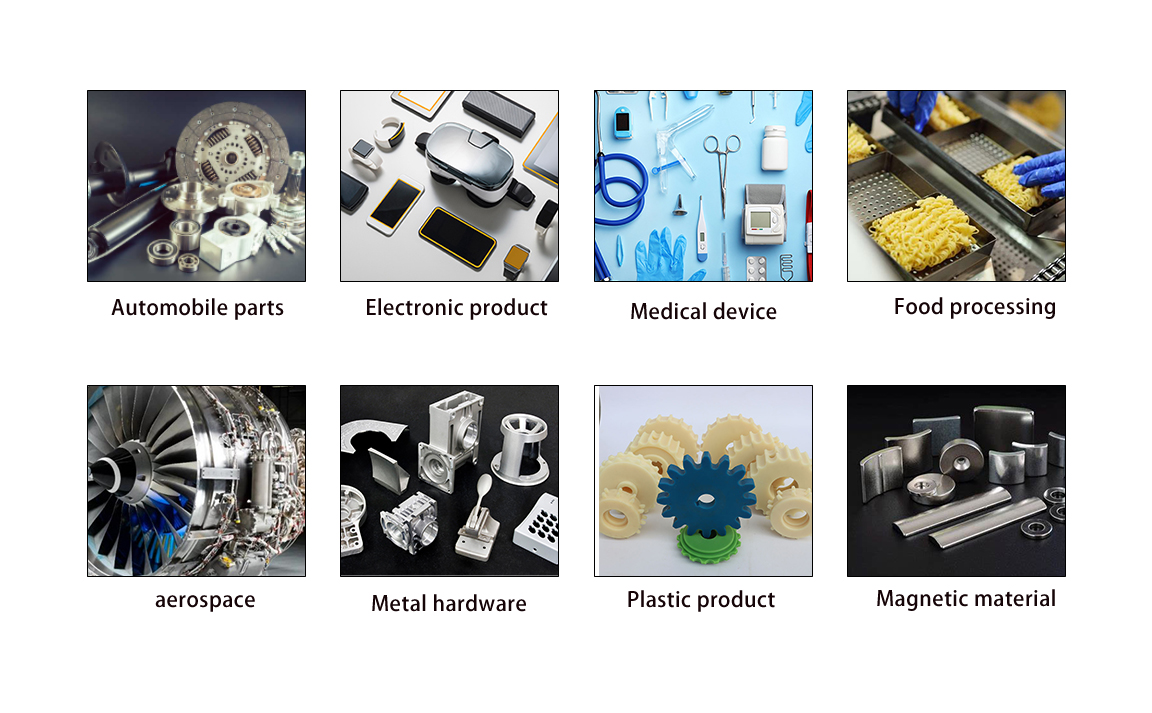

Scope of application | It is suitable for the detection of rubber parts, precision hardware parts, automobile, mobile phone parts, plastic parts, electronic parts and other high-precision products. |

Optical system | Germany high rate CCD industrial camera, Japan imported lens, professional light source system |

Number of cameras | 1 as standard (up to 4 can be configured according to demand) |

Image detection software | Siptech Vision inspection System |

Detection speed | A test time 50ms (depending on manual loading and unloading speed) |

precision | Up to ±0.005mm |

Recommended inspection size | 0.1 to 80mm |

Detection quality | 0.1 to 1000 GB |

Detection index | Dimension measurement: length, width, radius, center distance, line distance, Angle, etc |

Other: character recognition, appearance detection, classification recognition, bar code detection, printing detection |

Supply voltage | Ac 220V, 50Hz |

Rated power | 1kW |

Equipment weight | About 20kg |

Operating temperature | -3 ° C to 45 ° C |

Storage temperature | -20℃ ~ 60℃ |

Equipment size | 350mm(L)×250mm(W)×790mm(H) |