Visual optical screening machineBack

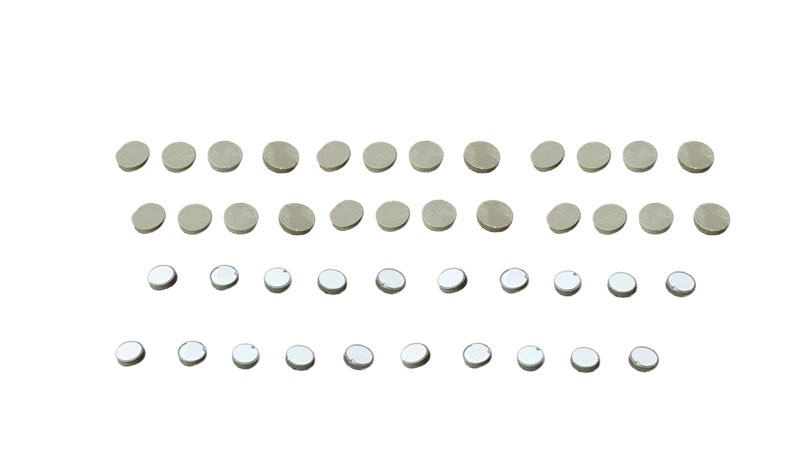

Product description:Optical screening machine is a kind of equipment that uses optical technology to screen and classify materials, which is usually used in waste treatment, food processing,

Product description:Optical screening machine is a kind of equipment that uses optical technology to screen and classify materials, which is usually used in waste treatment, food processing,

Optical screening machine is a kind of equipment that uses optical technology to screen and classify materials, which is usually used in waste treatment, foo d processing, ore sorting and other fields.

High efficiency: Automatic sorting can be achieved, greatly improving production efficiency and reducing labor costs.

Accuracy: Through advanced image processing algorithms, different materials can be accurately identified and classified.

Adjustable: Parameters can be adjusted according to different materials and requirements to adapt to a variety of application scenarios.

Environmental protection: helps to reduce the waste of resources and environmental pollution in the process of waste treatment.

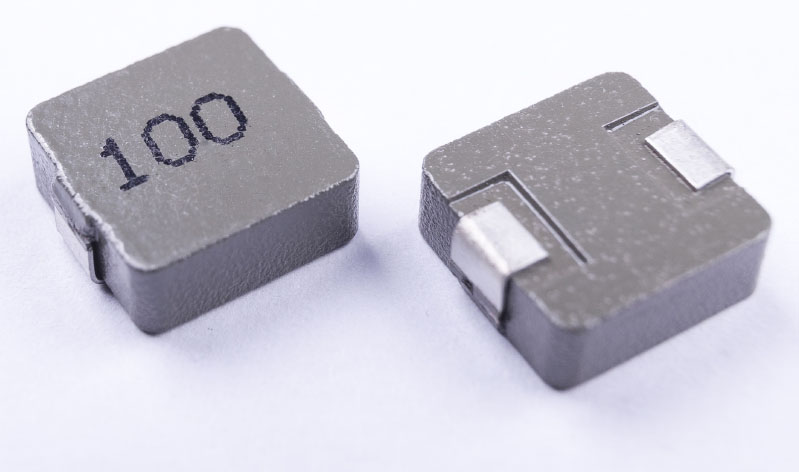

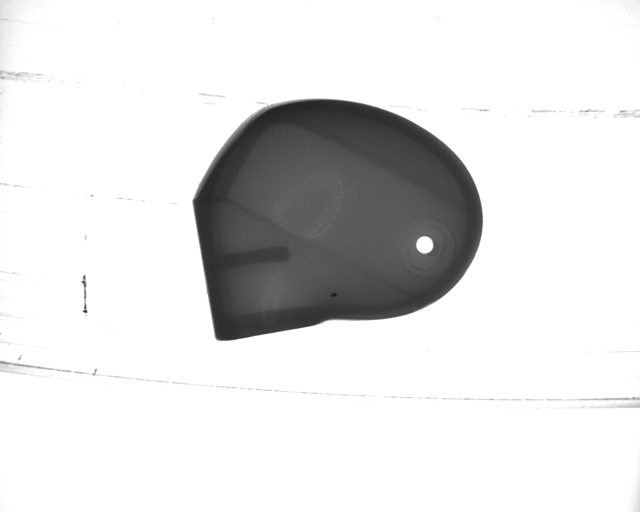

Sensor technology: The optical screening machine captures the specific characteristics and properties of the material surface by carrying different types of sensors, such as cameras, infrared sensors, X-ray sensors, etc.

Image processing: The captured images are analyzed by advanced image processing algorithms to identify and classify different materials.

Air sorting: According to the preset classification standards, the material is sorted and classified by air or other mechanical devices.

Device type | High speed cloud disk tester (Glass disk) |

Scope of application | Suitable for testing screw products that can be placed smoothly. |

turntable | Special ring glass turntable |

Optical system | Germany high rate CCD industrial camera, Japan imported lens, professional light source system |

Number of cameras | Three are standard |

Control system | Industrial computer |

Image detection software | Siptech Vision inspection System |

Feed system | Special feed guide rail, a set of vibration disk equipment, automatic feed storage hopper equipment (optional) |

Packaging system | Automatic counting and packing machine (optional) |

Detection speed | 200 to 1200 PCS/min |

precision | Up to ±0.01mm |

Recommended inspection size | 2 ~ 15mm |

Detection quality | 0.1 to 100g |

Detection index | Appearance size detection: screw bottom shape, screw head shape, screw inner and outer diameter, tooth distance, tooth Angle, step height, head height, etc |

Defect detection: 360-degree, there are no teeth, oblique teeth, bad rubbing teeth, burrs, solder joint area, marks, there are no internal teeth, all functions of standing flat head screw tooth parts can be detected | |

Supply voltage | Two-phase 220V, 50Hz |

Rated power | 1kW |

Atmospheric pressure | The air pressure is not less than 0.35 ~ 0.7MPa |

Equipment weight | About 500kg |

Operating temperature | -3 ° C to 45 ° C |

Storage temperature | -20℃ ~ 60℃ |

Equipment size | 1000mm(L)×1000mm(W)×1800mm(H) |

Waste treatment: for the recycling of valuable substances in waste, such as the sorting of plastics, glass, metals, etc.

Food processing: It can be used for the detection and elimination of foreign bodies or defective products in food to ensure product quality and safety.

Ore separation: used for the separation of useful minerals and waste rocks in ore, improve the efficiency of ore mining.

Seed treatment: In seed processing, it can be used to remove unhealthy, mutated or infected seeds to ensure seed quality.

Waste treatment Food processing Ore separation Seed treatment

Service hotline