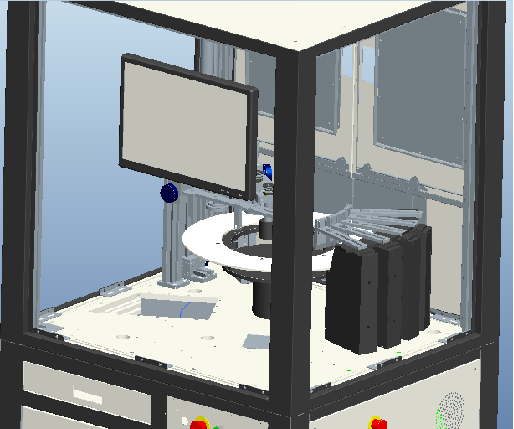

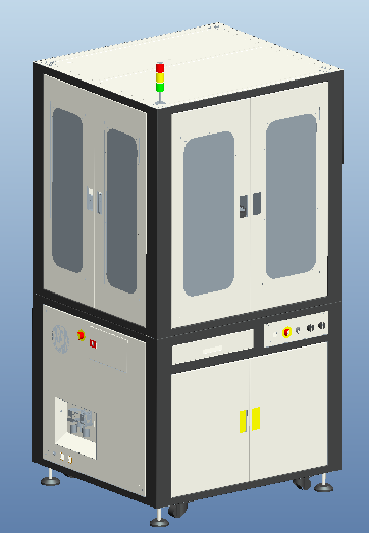

Detection scheme for plastic parts in cloud disk high-speed detection machine

The molding detection of plastic parts mainly detects various heights and shapes of columns, blocks, strips, etc. Because some products may not have enough material for the column when molding, or a block is only half like this. Therefore, some tests need to be carried out.

After the injection molding process, the plastic defects are defected. Sptek recommends using a cloud disk high-speed visual detector.

Cloud disk high-speed vision detector, because imaging needs to be considered in the height direction, conventional forward view imaging may not be able to see if there are relevant components. Here are two ways to consider. One is to tilt the product (or camera) to see whether the product meets the requirements from the side. The other is to shoot with a 3D camera to get its related height curve. However, no matter which method is used, it may face shadows, blocking and other problems. Therefore, it is recommended to use shadowless series light sources such as dome shadowless light sources and four-sided shadowless light sources. The effect should be better.

Detect the effect

Lack of glue

Image.png

-

Service hotline

19926638772