Appearance testing scheme for plastic parts

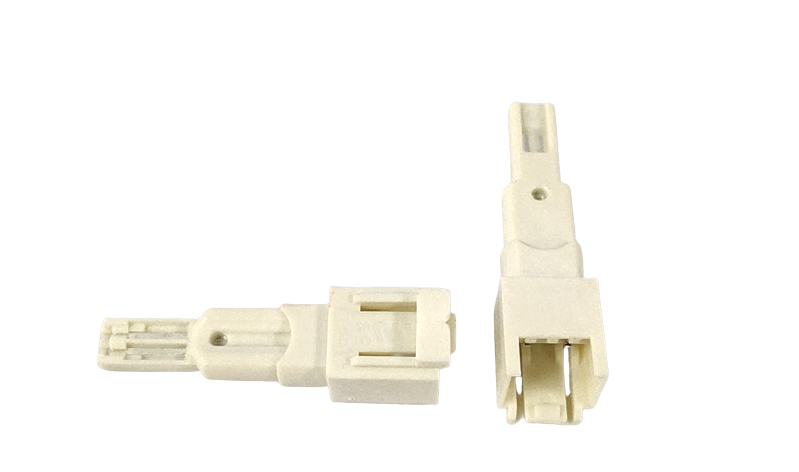

Automotive connectors refer to electrical connectors used to connect different parts or systems in vehicles. The connector allows electrical signals, power supply and data to be transmitted between various parts of the car, such as engine control units, sensors, dashboards, lighting systems, etc. Automotive connectors play a vital role in modern cars and must have good electrical connection performance, durability, waterproof performance and vibration resistance.

Automotive connectors are usually designed into different types and specifications according to their uses and connection needs, such as plug connectors, terminal connectors, board-to-board connectors, etc. These connectors can provide a different number of sockets, pins and circuits as needed to adapt to various electrical connection requirements.

The design and selection of automotive connectors are crucial to the reliability, performance and safety of automotive electrical systems. Therefore, automobile manufacturers and suppliers usually choose the appropriate connectors according to specific requirements and standards to ensure the normal operation and stability of the entire vehicle system.

In the production process of automobile connectors, the size detection of defective products, internal groove effusion, cracks, cracks and other appearance detection. Sputak recommends the use of cloud disk high-speed visual detector.

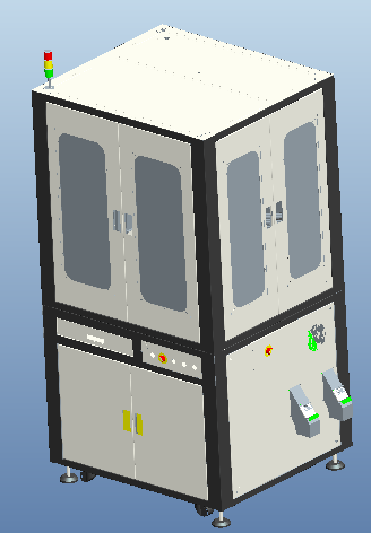

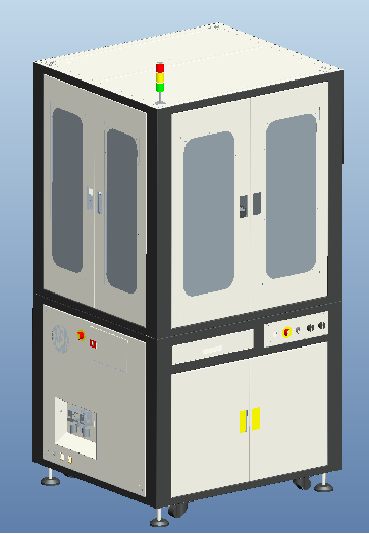

High-speed vision detection machine is a device specially used for high-speed vision detection and image processing. Equipped with a high-resolution camera, light source system and advanced image processing software, it can capture, process and analyze product images in a very short time. High-speed visual inspection machines are widely used in industrial production lines to detect and screen defects, foreign bodies, size deviations and other problems in products to ensure product quality and production efficiency.

The working principle of the high-speed visual detector is to quickly obtain the product image through the camera, and then use the image processing algorithm to analyze and compare the image to identify any unqualified parts. It can achieve a fast detection speed of milliseconds and is suitable for automatic detection tasks on high-speed production lines.

The advantages of high-speed visual inspection machine include high efficiency, high precision and reliability. Help enterprises improve product quality, reduce production costs and improve production efficiency. At the same time, the high-speed visual inspection machine can also help enterprises achieve unmanned production and improve the automation level of the production line. These machines are widely used in many industries, such as electronic manufacturing, automobile manufacturing, food processing, etc.

Detection effect

The baffle is out of material.

The buckle is short of material.

PIN is crooked

Less PIN

PIN crush

-

Service hotline

19926638772