Vertical one-key measuring instrument, professional identification of ceramic authenticity!

Ceramic parts are a common industrial part and are commonly used in a variety of processes and applications. Ceramic parts are widely used in electronics, aerospace, automotive, medical equipment and other fields, for insulation, heat conduction, wear resistance, sealing and other functions.

Ceramic parts in the process of processing lead to delamination, folding film, magnetic leakage, impurities, extrusion knife and other defects. It is recommended to use a vertical one-button measuring instrument, which can detect up to 130 pieces per minute.

The vertical one-button measuring instrument is a simple and easy to use measuring device that is commonly used for rapid measurement and quality control on industrial production lines. Vertical one-button measuring instrument plays an important role in modern manufacturing, helping enterprises to simplify the measurement process, improve the measurement accuracy, and speed up the quality inspection process of products.

Equipment characteristics

One-click operation

The vertical one-button measuring instrument has a simple and easy-to-use design that allows measurement to be done with the push of a button without complicated setup and operation.

Vertical design

The equipment adopts vertical design, which is convenient for the operator to place the product on the measuring table for measurement and improve the operation convenience.

Rapid measurement

Through fast data acquisition and automatic processing, the vertical one-button measuring instrument can quickly complete the measurement process and improve production efficiency.

High precision

With high-precision measurement sensor and precision measurement algorithm, it can achieve accurate measurement results.

versatility

In addition to the basic size measurement, the vertical one-touch measuring instrument can also perform a variety of functions such as shape recognition, Angle measurement, surface quality assessment, and so on.

Data display

The measurement results can be displayed directly on the screen of the device or through the connection of an external device, which is convenient for the operator to view and record.

Wide applicability

The vertical one-button measuring instrument is suitable for various industries, such as electronics, machinery, automotive, etc., for product quality control and inspection.

Automatic function

Part of the vertical one-button measuring instrument has automation function and can be integrated with the production line to realize automatic measurement and data processing.

Main function

Fast measurement: Through one-click operation, to achieve fast and convenient product size measurement, improve production efficiency.

Multi-dimensional measurement: It can measure the length, width, height and other dimensions of the product to meet the measurement needs of different products.

Shape recognition: It can identify the shape features of the product, including curves, angles, contours, etc., and make corresponding measurements.

Data display and recording: Measurement results can be displayed directly on the device screen, and data can be recorded, saved or output for subsequent analysis and reporting.

Automation function: Part of the vertical one-button measuring instrument has automation function, which can realize automatic measurement, data processing and alarm function, reducing manual intervention.

Flexibility: Supports the measurement of a wide range of product types and sizes, and can be customized to meet the measurement needs of different industries.

Real-time monitoring: It can monitor product size and shape changes in real time, detect anomalies in time and remind operators to deal with them.

Quality control: Help enterprises to carry out product quality control and inspection to ensure that products meet specifications.

Easy to operate: It has a simple and easy to understand operation interface and one-click operation, reducing the technical requirements of the operator and improving the efficiency of use.

Equipment composition and main organization

Visual inspection software: SIPOTEK

Industrial computer: Custom made by SIPOTEK

Display: PHILIPS 19 "LCD display

Industrial camera: Visual line scan camera

Camera adjustment module: customized by SIPOTEK

Industrial lens: Telecentric HD optical industrial lens

Ring light source: Custom optical adaptive light source

Control system: customized by SIPOTEK

Test fixture: customized by SIPOTEK

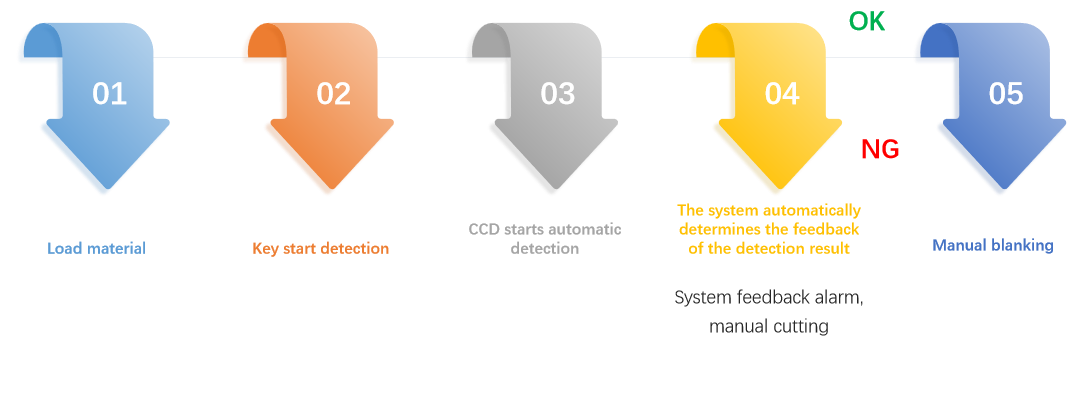

Detection process

Detection effect

Impurity detection is possible

Squeegee detection

Folding film detection

Magnetic leakage detection

Layered detection

-

Service hotline

19926638772