Cloud disk high-speed testing machine brass part size detection scheme

Brass parts refer to parts or parts made of brass material. Brass is an alloy mainly composed of copper and zinc, with good mechanical properties, electrical conductivity and corrosion resistance. Due to its excellent properties, brass is widely used to manufacture various parts and parts, covering many fields. Brass parts are common in industrial manufacturing and are used to manufacture valves, pipe fittings, bolts, nuts, bearings, joints, connectors and other mechanical parts. The wear resistance and corrosion resistance of brass make it an ideal material choice for many mechanical equipment and industrial applications.

In addition to the industrial field, brass parts are also widely used in home decoration, building materials, music equipment and other fields. For example, brass parts can be used to make door handles, lamps, decorations, etc., giving the product an elegant appearance and texture.

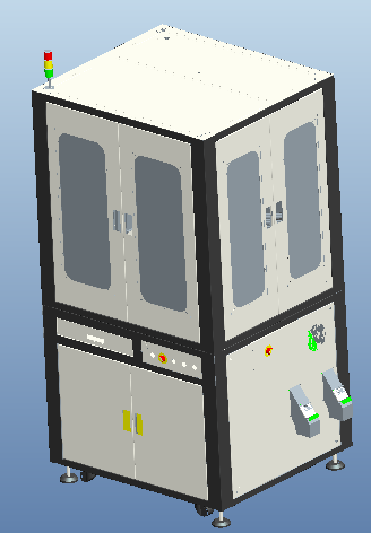

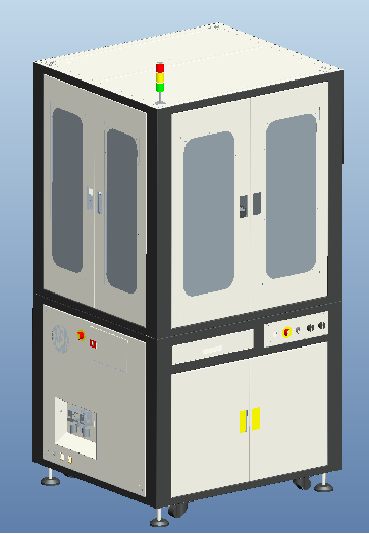

In this case, the customer needs the size detection of brass parts, and Sputek recommends using a cloud disk high-speed visual detection machine.

"Cloud disk high-speed visual detector" may refer to a high-speed visual detection device used to detect cloud storage devices or cloud server hard disks. This device combines visual technology and high-speed detection system to quickly and accurately detect various features and indicators of cloud disk products. The cloud disk high-speed visual detector may use advanced image processing algorithms and high-speed camera equipment to detect and analyze the appearance, logo, size, defects, etc. of the cloud disk. This device helps to ensure that cloud disk products meet quality standards, improve production efficiency and reduce human error. Through the automated high-speed visual inspection machine, manufacturers can achieve fast and accurate product testing and improve the efficiency and quality control level of the production line.

Detection effect

Size detection

-

Service hotline

19926638772