Appearance detection scheme of inner hexagonal screws

The inner hexagonal screw is a kind of screw whose threaded head is designed as a hexagonal groove, which is used to accept tools such as the inner hexagonal wrench or torque wrench for installation and removal. It makes the inner hexagonal screw easier to use in closed spaces or requires high torque, because the inner hexagonal tool can provide better handling and torque transfer efficiency. The design of the inner hexagon screw head enables it to effectively transfer torque and is easier to install and disassemble, especially for parts that need to be removed frequently.

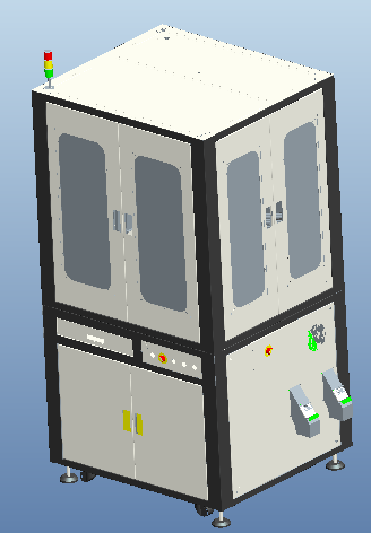

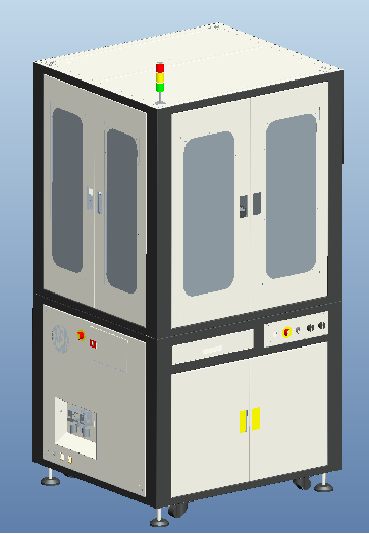

In the production process, the inner hexagonal screw has defects such as burr, repeated saw groove, round head, unrubbed wire, two-way unfinished, biting neck, rubbing, thread burning, different hearts, etc. Sputek recommends the use of cloud disk high-speed visual detector.

High-speed visual inspection machine is a special equipment for fast and efficient visual inspection and quality control of products on the production line. Equipped with a high-performance camera, light source and image processing system, it can quickly capture and process a large number of product images in a short time, and accurately identify and analyze defects, foreign objects or other quality problems on the product surface. Automatically classify, screen and alarm products.

Detection effect

Repeated sawing groove

Round head

Burr

Bite the neck

Unkneared silk

Rubbing

-

Service hotline

19926638772