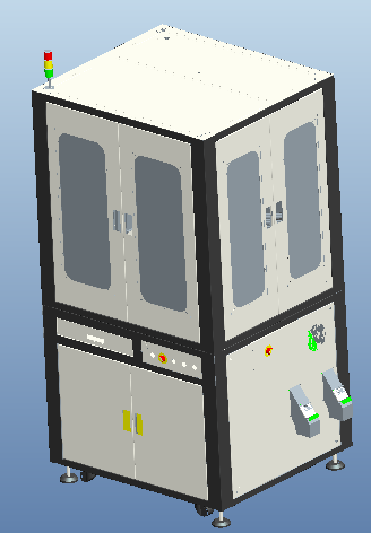

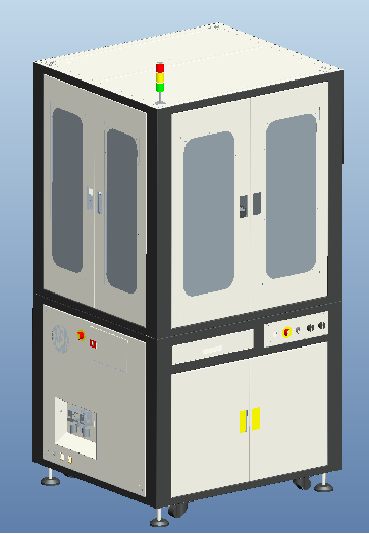

Screw size detection scheme of cloud disk high-speed visual inspection machine

Welding nuts are a method used to fix metal components. Usually, the welding nut is achieved by placing the nut on the metal surface and then welding it to the metal surface by arc welding or other welding methods. It is used to provide a fixed connection point when the bolt or nut cannot be fixed directly to the metal member. Welding nuts are usually used in applications that require stronger connections to ensure a stable connection between metal components. The use of welding nuts requires certain welding skills and experience to ensure the quality and reliability of welding.

The nut has some defects in the production process, and it is necessary to use the Sputek cloud disk high-speed vision detection machine to detect the height, diameter, R angle, angle and other appearance size detection.

High-speed visual inspection machine is an automated system for rapid detection of products or workpieces. Use high-resolution cameras and advanced image processing algorithms to detect the quality, size, shape, color or other characteristics of the product. High-speed visual detection machine is widely used in production lines, which can achieve fast and accurate detection and improve production efficiency and quality control. Capture and process images at a very fast speed, so as to achieve efficient production line detection. The design and configuration of the high-speed visual detector may vary according to application and requirements, but its core function is to use advanced visual technology for rapid and accurate detection and analysis.

Detection effect

Cammed detection

Round hole distance

The size of the hole can be checked

Angle

-

Service hotline

19926638772