Transformer skeleton visual appearance inspection

Arc machine vision inspection equipment is a machine vision equipment used to detect curved or curved objects. Cameras and image processing algorithms are used to detect, identify and measure various features and attributes of curved objects. Arc machine visual inspection equipment is widely used in industrial production, for quality control, automatic production and product inspection and other fields.

Device function

High precision detection

Arc machine visual inspection equipment with high precision detection ability, can identify the shape of the object, size, position and defects and other features.

Automatic processing

The equipment is equipped with automated image processing algorithms, which can process large amounts of image data in real time, improving production efficiency and accuracy.

Data analysis and recording

The equipment can analyze and record the detected data to help users with quality control and production optimization.

Visual interface

Usually the equipment has an intuitive visual interface, which is convenient for the operator to monitor and control.

Equipment composition

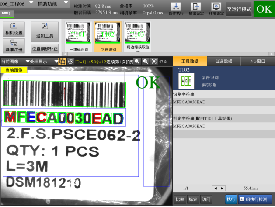

Visual inspection software

Industrial computer

display

Industrial camera

Camera adjustment module

Industrial lens

illuminant

Detection platform

Servo motor

Control system

PLC motion collaboration

Principle of equipment detection

Detected object

The transformer skeleton refers to the main structural components that support and hold the transformer core and coils. Made of metal material, it is used to support the internal components of the transformer to ensure its structural stability and mechanical strength. The design and manufacture of the transformer skeleton should take into account the rated power, voltage and other parameters of the transformer to ensure the normal operation and safety of the transformer.

Some defects of the transformer skeleton during production, such as missing needles, crooked needles, missing corners or other defects on the surface.

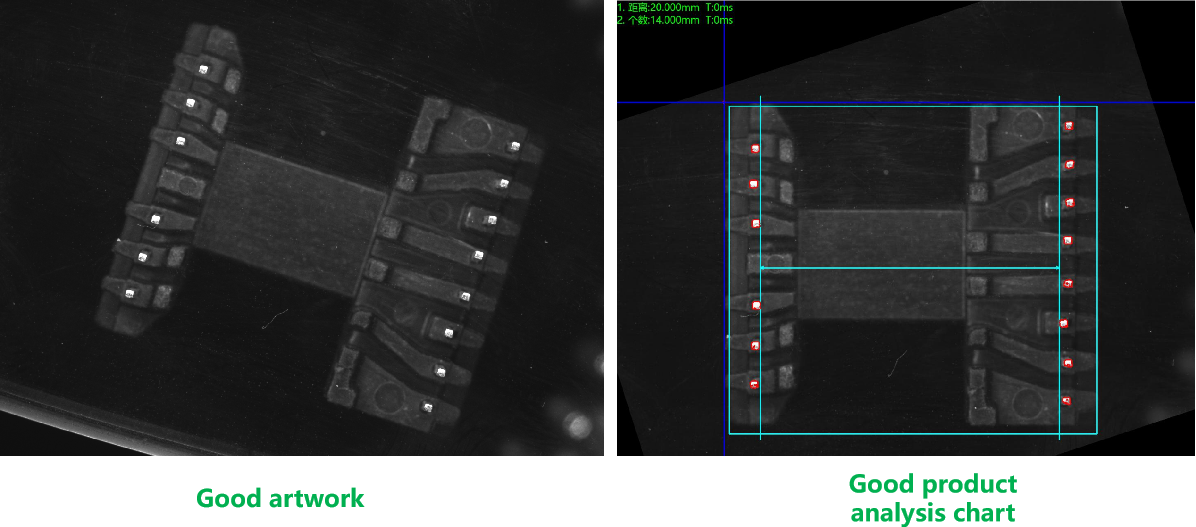

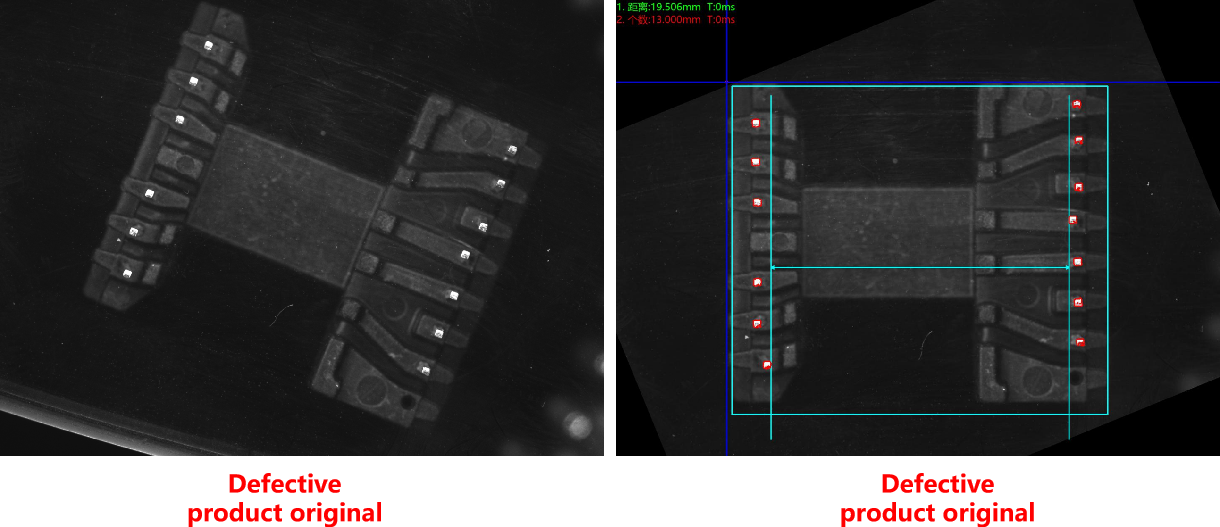

Detection effect

Bottom positive light detection good product analysis diagram: OK

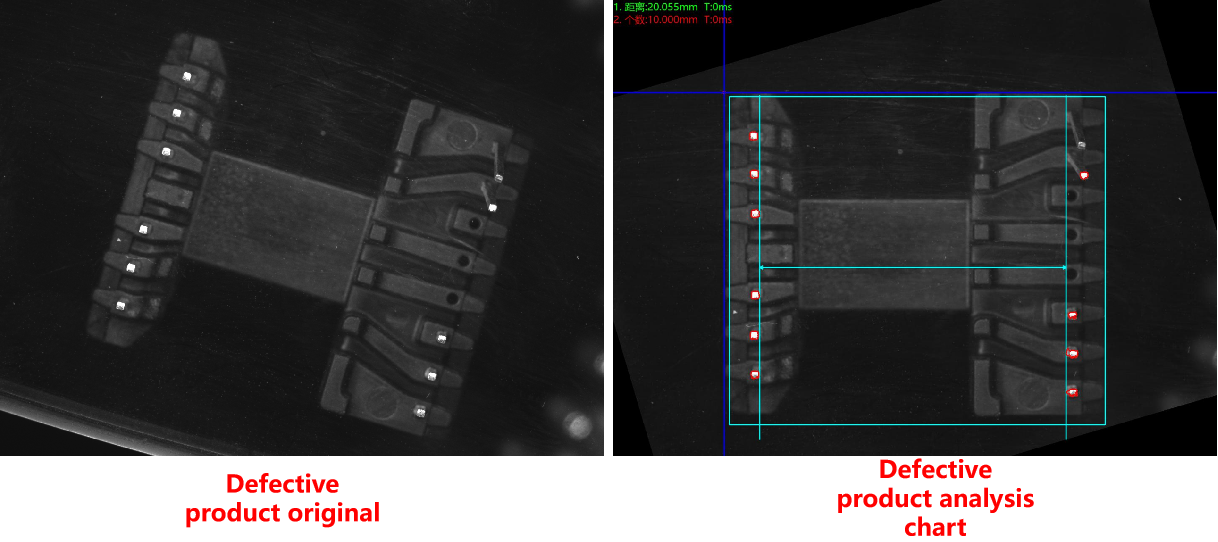

Bottom positive light detection of defective products analysis diagram: NG bad features: less needles

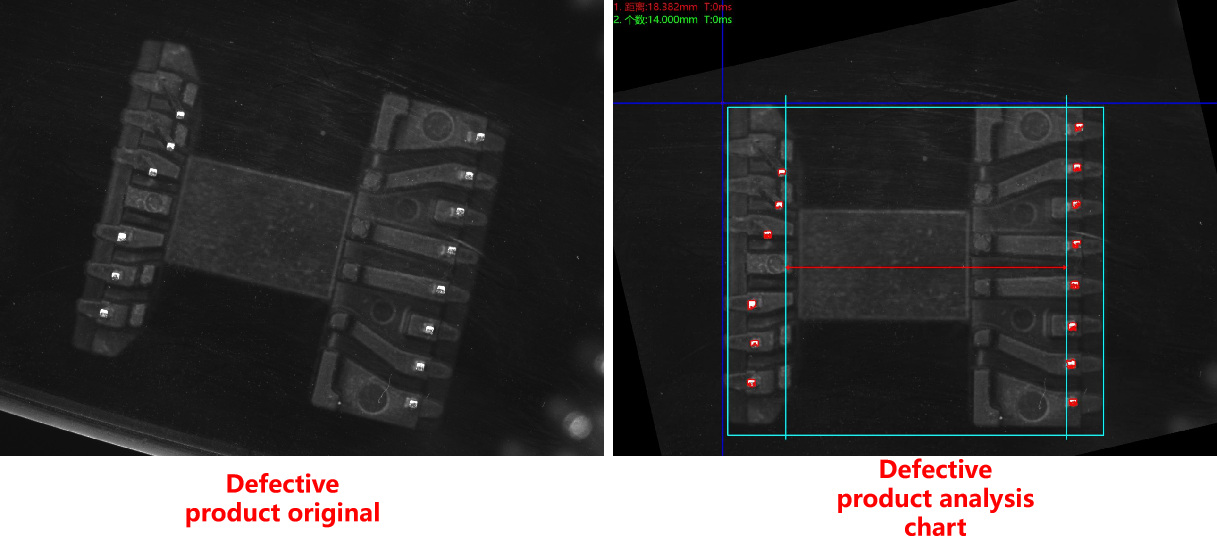

Bottom positive light detection of defective products analysis diagram: NG bad features: less needles

Bottom positive light detection of defective products analysis diagram: NG bad feature: crooked needle

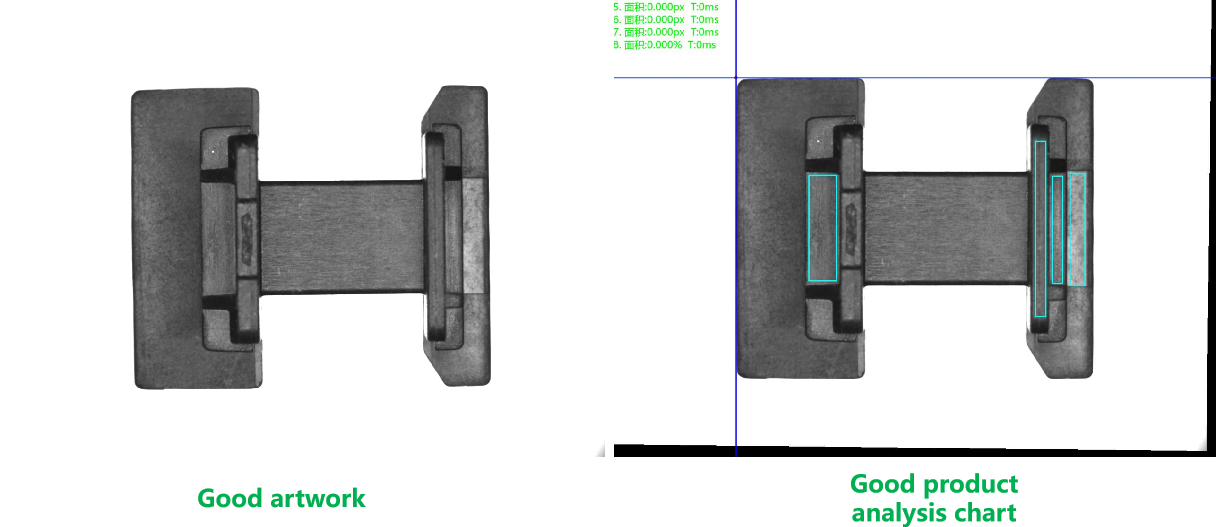

Top positive light detection good product analysis diagram: OK

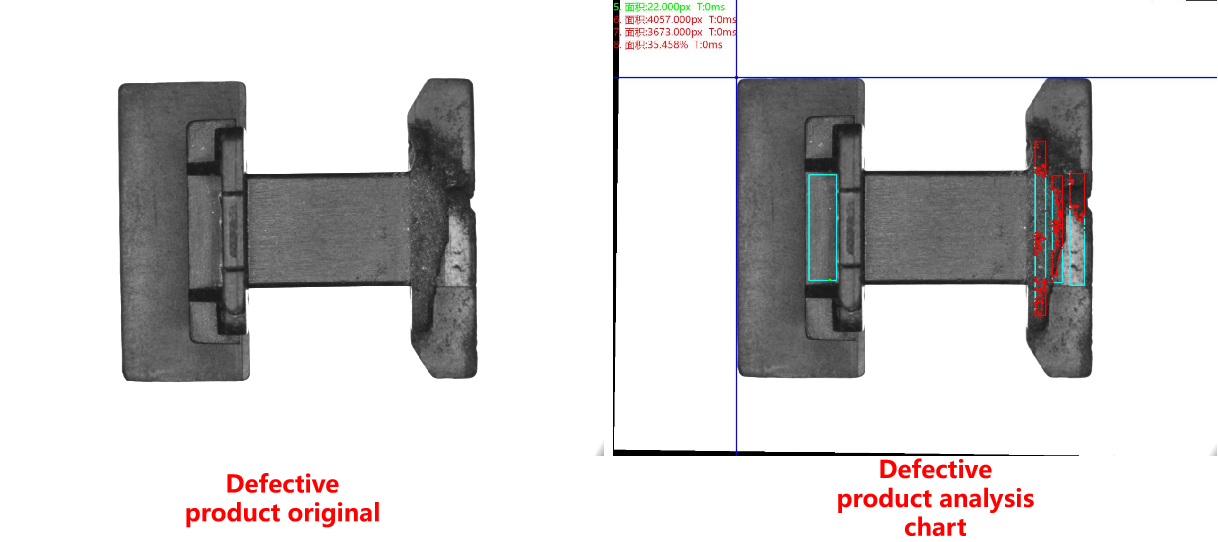

Top positive light detection of defective products analysis diagram: NG Bad feature: missing corners

-

Service hotline

19926638772