Is it difficult to identify defects in electronic components? Let's see how this device is cracked!

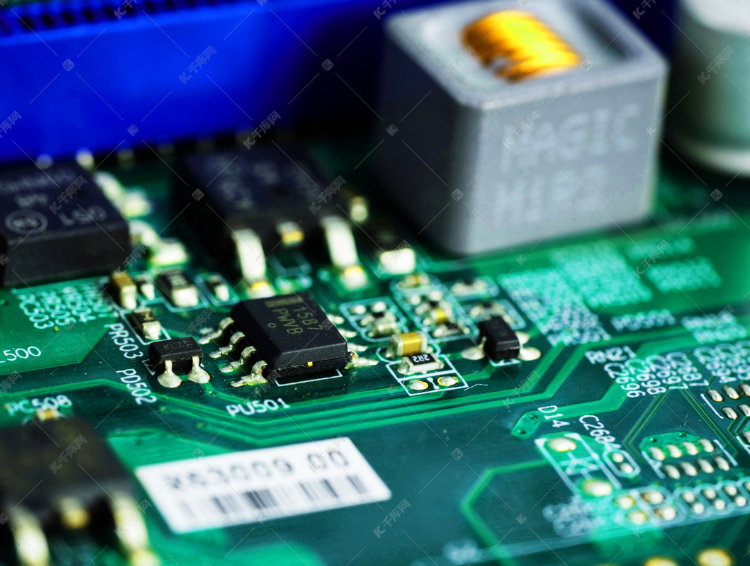

Electronic component appearance defect detection equipment is a kind of professional equipment used to detect the appearance defects of electronic components. With the wide application of electronic components, the requirements for their quality and reliability are getting higher and higher. The appearance defect of electronic components is one of the important factors affecting their performance and life. Therefore, it is of great significance to develop an efficient and accurate appearance defect detection equipment for electronic components to ensure the quality of electronic products.

The appearance defects of electronic components mainly include surface defects, size deviations, welding problems, etc. These defects may lead to reduced performance, unstable operation or even complete failure of electronic components. Therefore, early detection and repair of these defects is essential to ensure the reliability of electronic products.

The appearance defect detection equipment of electronic components can efficiently detect the appearance defects of electronic components by using advanced optical imaging technology and image processing algorithms. The equipment can carry out all-round detection of electronic components, including appearance defects, size deviation, welding quality, etc. At the same time, the equipment also has the characteristics of high speed and high precision, and can complete the detection of a large number of electronic components in a short time.

The working principle of electronic component appearance defect detection equipment is to use optical imaging technology to shoot electronic components, and to analyze and identify the captured images through image processing algorithms. By comparing sample images with standard images, it can accurately determine whether there are cosmetic defects in electronic components. At the same time, the device can also measure the size of electronic components and compare them with the standard size to determine whether there is a size deviation. In addition, the equipment can also evaluate the welding quality to ensure the reliability of welding.

The appearance defect detection equipment of electronic components has a wide application prospect in the electronic manufacturing industry. It can help enterprises improve product quality and production efficiency, and reduce the rate of defective products and production costs. At the same time, it can also improve the competitiveness of enterprises and win more market share.

Electronic component appearance defect detection equipment is a very important professional equipment, which is of great significance to ensure the quality of electronic products. Through advanced optical imaging technology and image processing algorithms, the appearance defects of electronic components can be detected efficiently and accurately to ensure the reliability and stability of the product. It is believed that with the continuous progress of science and technology, the appearance defect detection equipment of electronic components will play an increasingly important role in the electronic manufacturing industry.

-

Service hotline

19926638772