PCB board visual defect detection equipment function

PCB board visual defect detection equipment helps improve the quality and efficiency of PCB board production in industrial manufacturing, reduce human error, and automate the production process.

The industrial robot is used to detect various defects on the surface of the PCB board, such as short circuit, open circuit, poor welding, oxidation, deformation, etc., to ensure the quality and reliability of the PCB board.

The vision system accurately locates the components, resistors, capacitors, chips, etc., on the PCB board for subsequent machining or welding operations. The robot vision system is used to detect the quality of solder joints on PCB board, including whether the welding is uniform, whether there are problems such as virtual welding, welding ball, welding slag, etc.

Visual inspection of the logo, bar code or two-dimensional code on the PCB board for traceability of product information or quality control.

Detect the correct placement of the components on the PCB board, the correct orientation, and the damage or missing of the components.

The robot vision system is used to detect PCB surface defects, scratches, stains, damage, etc., to ensure product appearance quality.

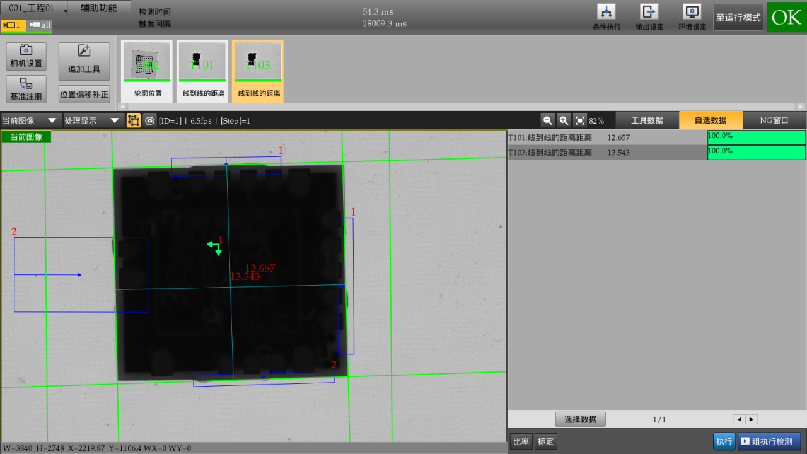

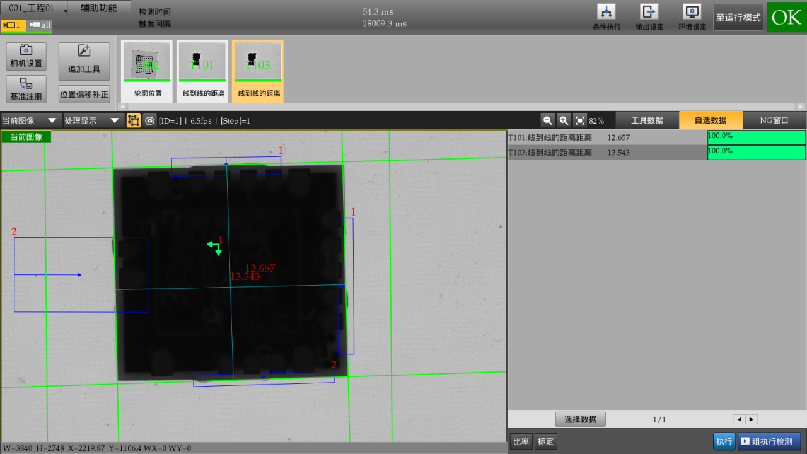

The dimensions of components on the PCB board are measured by the robot vision system to ensure compliance with specifications.

The robot vision system can conduct comprehensive inspection and analysis of the PCB board, achieve quality control, and improve production efficiency and product quality.

-

Service hotline

19926638772