Cloud disk high-speed detection machine silicone part defect detection scheme

Automotive silicone connector waterproof plug is a component used in automotive electrical systems, which is usually used to waterproof, seal and protect connectors. These waterproof plugs are usually made of silicone materials and have excellent high temperature resistance, low temperature resistance, chemical corrosion resistance and aging resistance.

It is used at the connector to prevent water, moisture or dust from entering and protect the connector and electrical system from damage. Silicone materials can maintain stable performance in high-temperature environments, which is suitable for applications in high-temperature areas such as automobile engine compartments. The silicone material is soft and easy to bend and can adapt to connectors of different shapes and sizes. It has strong chemical corrosion resistance and is not easy to be eroded by lubricants or other chemicals. It is usually designed in a simple and easy-to-install form, which is convenient for use on the production line or during maintenance.

Silicone connector waterproof plugs play a very important role in automotive electrical systems to ensure the stability and long-term reliability of connectors. It helps to protect the vehicle's electrical system from moisture, dust and other external environments, and improve the reliability and durability of the vehicle.

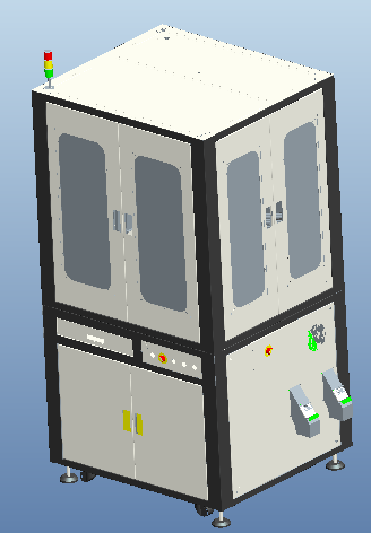

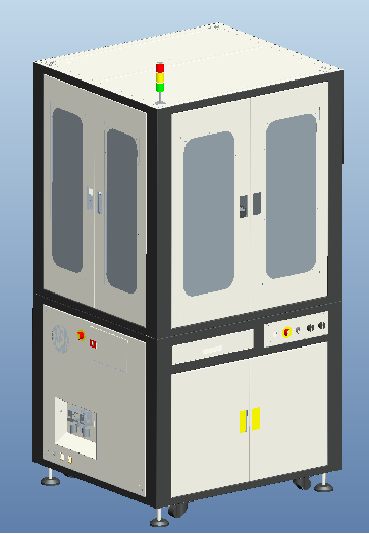

The connector has holes, shaping, lack of material and other defects in the production process. Sptek recommends using a cloud disk high-speed visual detector.

Cloud disk high-speed vision detector usually refers to a device or system that combines cloud computing, high-speed vision technology and automatic detection technology. It is used to automate production lines to detect the quality, shape, size or other characteristics of products or objects, and to make judgments or take corresponding measures quickly. With high-speed camera equipment and image processing algorithm, it can quickly capture and process a large amount of image information. Through cloud computing technology, more efficient data storage, processing and analysis can be achieved, and real-time monitoring and feedback can be supported. It can automatically identify and detect specific characteristics of products or objects, such as defects, size deviations, etc., to achieve automatic quality control. It has fast response and processing capabilities, which is suitable for real-time detection needs on high-speed production lines.

Detect the effect

Dirty

Block the hole

Cloak

Damaged

Lack of material

-

Service hotline

19926638772