Glass sheet detection scheme of cloud disk high-speed detection machine

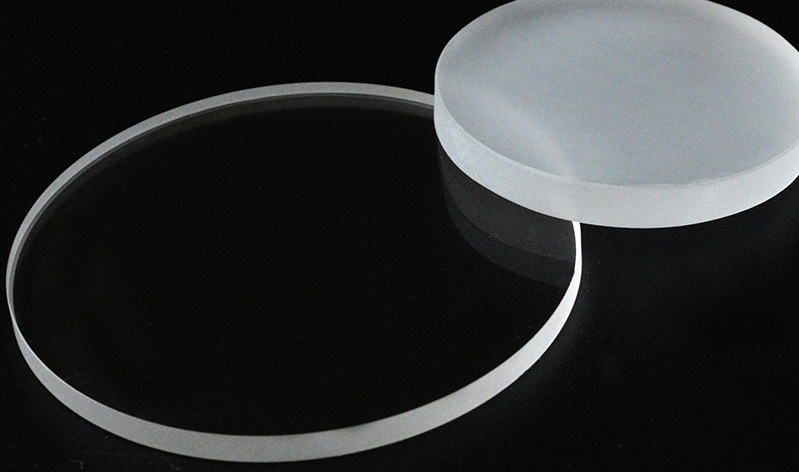

Glass chips usually refer to thin and flat glass pieces, which are often used in various applications. These pieces of glass can have different shapes, sizes and thicknesses, and have a variety of uses. Glass sheets are widely used in industry, architecture, scientific research, electronics, optics and other fields. They can be used as materials for windows, lenses, display screens, optical components, laboratory instruments, glassware, mobile phone screens, etc. Glass chips usually have the characteristics of transparency, heat resistance and chemical corrosion resistance, which can provide protection and aesthetic effect. Choose the right pieces of glass that can be customized according to specific needs to meet the requirements of different occasions.

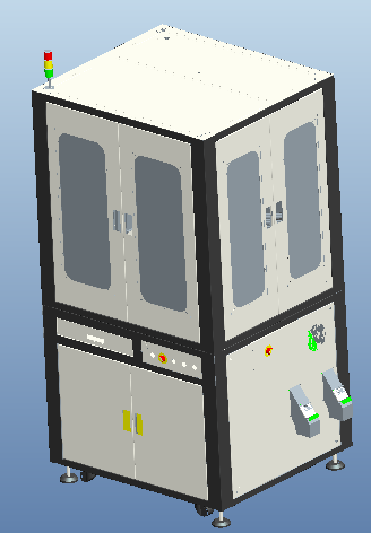

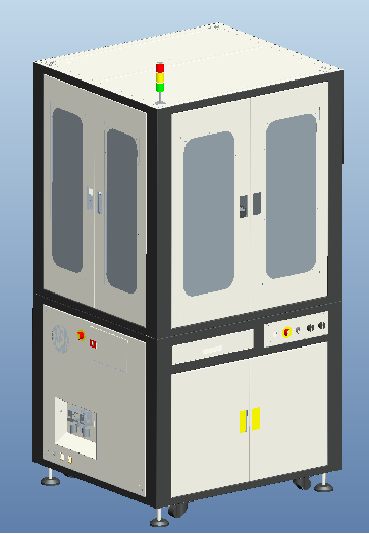

In this case, customers need to detect glass chips, and Sptek recommends using a cloud disk high-speed visual detector.

High-speed vision detector is a device that can detect products with high speed and accuracy in a very short time. This machine usually combines advanced vision technology, image processing algorithm and automatic control system, which can quickly capture and analyze product images and realize rapid detection of product quality and characteristics. High-speed visual detection machines are widely used in electronics, automobiles, medical devices, food and other industries, and are used to detect cosmetic defects, size deviations, assembly problems, etc. Through the high-speed visual detection machine, real-time monitoring and automatic detection can be realized on the production line to improve production efficiency and product quality. This kind of equipment plays an important role in modern manufacturing, helping enterprises improve their competitiveness and meet the needs of high-quality products.

Detect the effect

-

Service hotline

19926638772