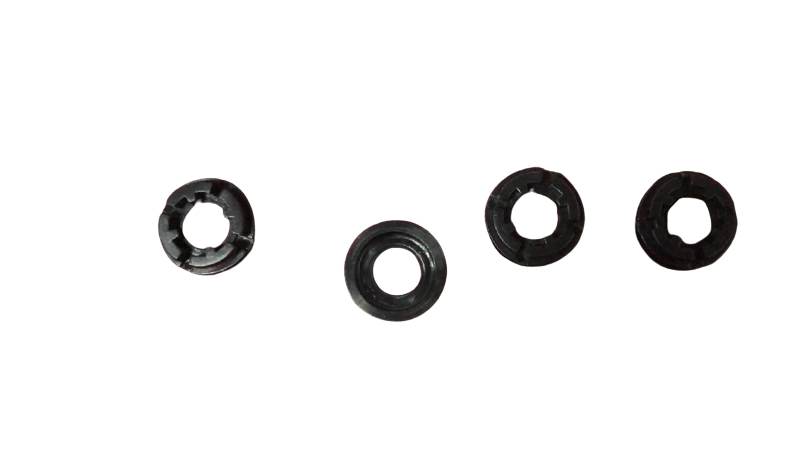

Appearance inspection scheme of bearing washers

Bearing is a component used to support rotating mechanical parts, which is usually used to reduce friction and support the weight of the rotating shaft. The bearing makes the rotation of the shaft smoother, reduces friction resistance, and supports the weight of the shaft by deploying balls, rollers or sliding bodies internally. Bearings are widely used in various mechanical equipment, including automobiles, wind turbines, power tools, etc. Different types of bearings are suitable for different working conditions and load requirements, so it is necessary to consider their load capacity, rotational speed, durability and other factors when selecting bearings.

In the production process of bearings with poor size and appearance, Sputek recommends the use of cloud disk high-speed visual detection machine.

High-speed visual inspection machine is a kind of equipment used to automatically detect defects, sizes, shapes, colors and other characteristics of products or workpiece surfaces. This device usually combines high-speed cameras, image processing software and mechanical systems to capture, process and analyze image information on the surface of the product in real time. The high-speed visual inspection machine is widely used in the quality control process of the production line, which can detect quickly and efficiently, improve production efficiency and reduce human errors. These devices are widely used in electronics, automobiles, medical devices and other industries.

Detection effect

Brushing

Rough selvedge

-

Service hotline

19926638772