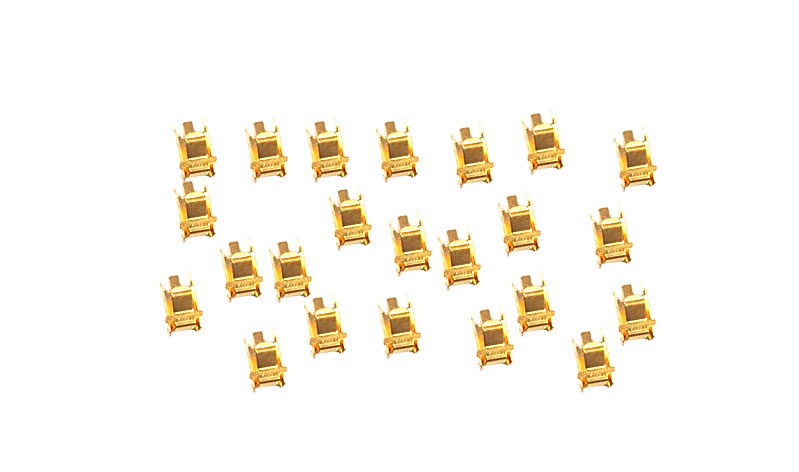

Machine vision technology helps hardware accessories size detection!

In the field of modern industrial manufacturing, the appearance and size of precision parts have extremely high requirements, aerospace, aviation, auto parts, electronic products and other fields, the performance of parts problems will affect the normal operation and use of functions.

In recent years, the rapid development of machine vision inspection technology has improved advanced science and technology for industrial automation production to effectively ensure product quality, machine vision inspection to help the production line achieve online real-time detection, measurement and automatic identification functions to improve efficiency and reduce factory costs, so as to maximize production benefits.

Therefore, machine vision inspection technology is widely used in the size detection of hardware accessories, surface defect detection, character recognition detection and so on.

Hardware parts visual inspection system through the identification of image features, analysis and calculation of the workpiece characteristic information, determine whether the product meets the requirements, and output control signals. The detection process is automatic detection, abnormal alarm signal is given, and the corresponding output OK or NG signal is also stored in the industrial computer picture of unqualified parts.

Hardware industry processing classic case based on machine vision

Detection content

Test the size of the product, and test the core size according to the outline displayed by the product photo.

Defect detection, such as obvious lack of material, scratches, etc., according to the imaging, the front light source can be used to determine whether there are surface defects. At present, according to the application of camera technology, the higher the pixel, the more obvious the judgment of microscopic defects.

Detection of contaminants, whether the surface is contaminated by other stains, etc., can be identified.

Integrity testing, whether the product is cracked, etc., or where there is missing processing.

Assembly verification, such as door hinges, whether the assembly is in place can be completed by visual inspection.

Detection efficiency: 180 pieces per minute.

Detection effect

wide

Size detection

-

Service hotline

19926638772