1 Second, 50+ Defects Detected! Plastic Buckle Inspection Ends the Era of ‘Human Error’

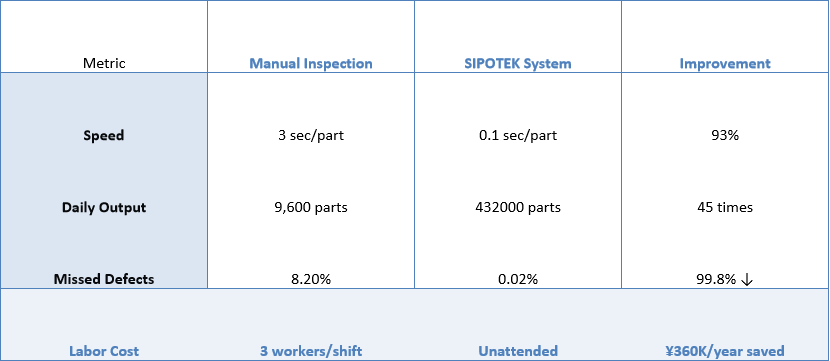

In precision manufacturing, a grain-sized defect in plastic buckles can scrap entire batches or even trigger safety incidents. Traditional manual inspection struggles with high-intensity, repetitive tasks—averaging 3–5 seconds per part with a staggering 8%–15% missed-defect rate, creating critical bottlenecks.

SIPOTEK Visual Inspection System, equipped with dual high-speed CCD cameras and AI deep learning, revolutionizes quality control:

Speed: 1 part/second

Accuracy: 99.98% defect detection rate

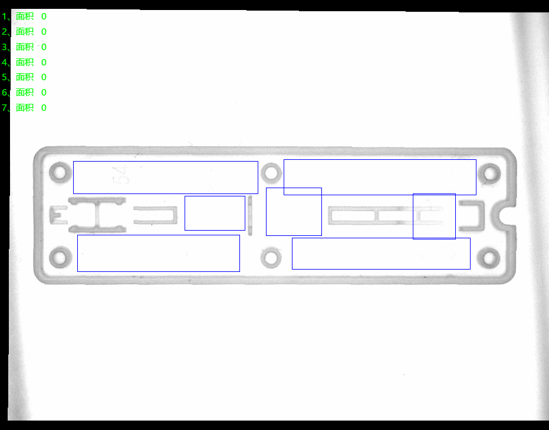

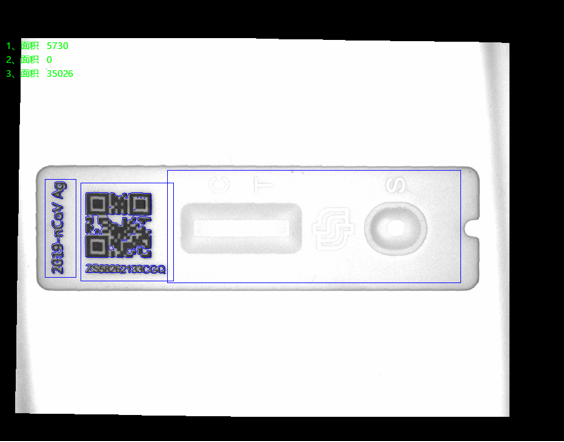

Dual-Camera Strategy: 50+ Defects Covered

Precision 360° inspection via synchronized cameras:

Top Camera (5MP):

Identifies surface contamination (≥0.1mm²), black spots (≥0.05mm), character absence/misprints (99.5% OCR accuracy), print misalignment (±0.05mm).

Side Camera (3MP):

Penetrates structural shadows to detect missing/broken posts (0.02mm precision), material shortage/burrs (99.9% accuracy), and deformations (±0.1° tolerance).

Field Test: 100K automotive buckles inspected—99.96% contamination detection rate, 0.002% false calls on missing posts.

3 Breakthroughs Solving Industry Pain Points

AI Anti-Interference Algorithm

Ignores plastic glare/color variations, reducing false alarms to <0.1% (vs. >5% in conventional systems).

Self-Evolving Deep Learning

Auto-updates detection models for new materials; changeover time cut to 30 minutes.

Micron-Level Positioning

±0.01mm repeatability with servo mechanisms ensures consistency.

Proven ROI: Efficiency & Cost Revolution

*Client case: A connector manufacturer reduced returns by 97%, avoiding ¥2.2M/year in losses.*

Safety Alert: Buckle Quality = Product Lifeline

A single missing post in an automotive buckle may cause:

→ Vibration-induced failure → Door rattling → Critical lock mechanism collapse

SIPOTEK’s 99.98% detection rate eliminates risks at 0.01mm-level defects.

Act Now, Leave "Human Inspection" Behind!

Request a free sample test and witness the efficiency revolution in 30 days.

Click to consult & claim your "Buckle Inspection Cost-Saving White Paper" + Custom ROI Report

Technical Specifications

Buckle Size: 5–50mm

Detection Accuracy: 0.02mm (0.0008")

Power: 220V AC

Materials: ABS/PP/PA66, etc.

-

Service hotline

13077808017